AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

Glentek, Inc. is a trusted provider of high-performance electric motors, specializing in innovative motion control solutions for a wide range of industries. We design and manufacture precision servo motors and amplifiers, delivering powerful and efficient performance for demanding applications. Our engineering expertise allows us to develop both standard and custom solutions, ensuring that each...

A leading supplier of high-performance motors and components, Chiaphua Components North America serves customers throughout the Americas and offers electric motors through the CCL & CIM Motor Products division. We supply motor solutions such as brushless motors, permanent magnet DC motors, induction motors, shaded pole motors, universal motors, vacuum cleaner motor, & gear motors.

More DC Motor Manufacturers

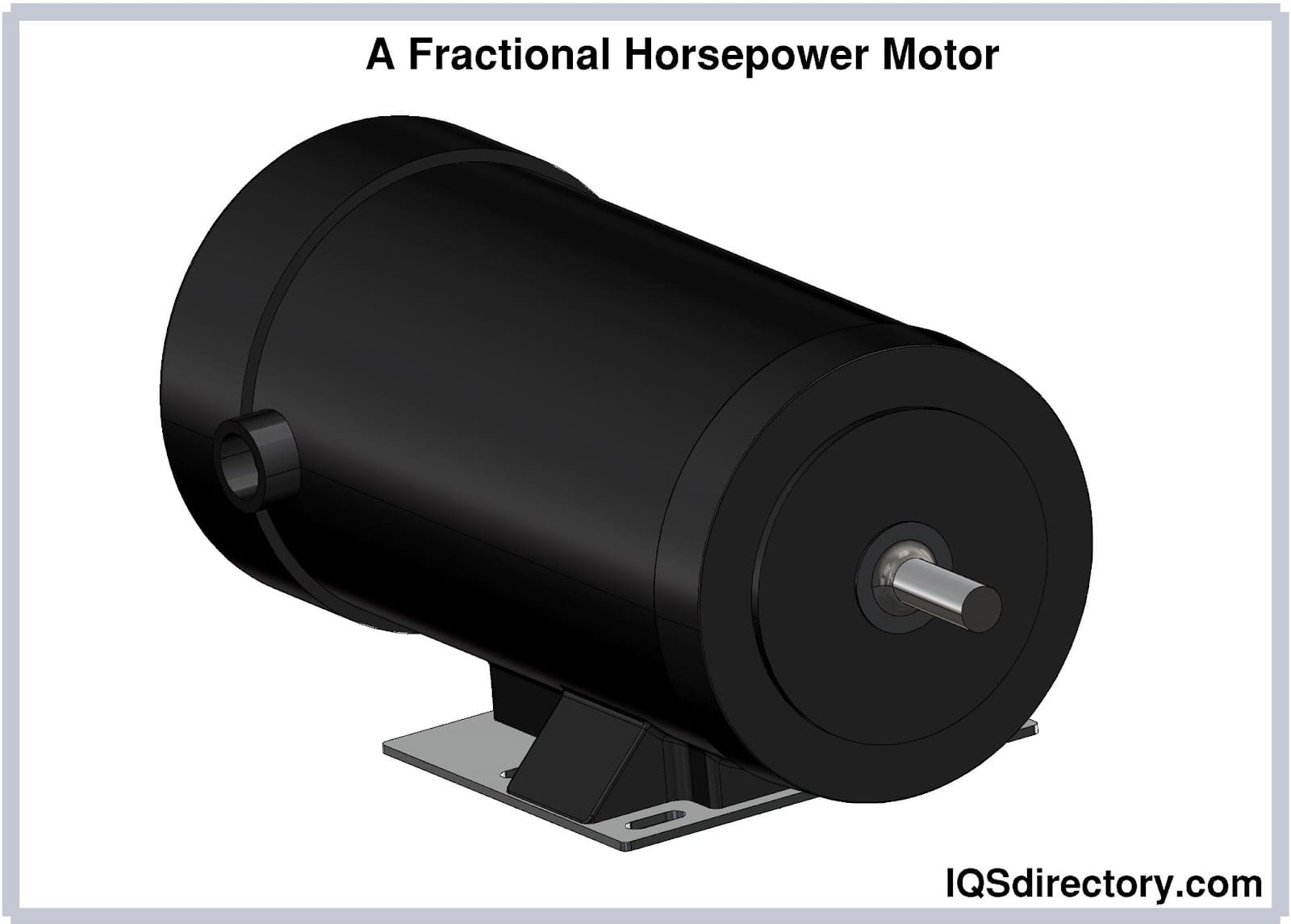

A direct current (DC) motor is an essential type of electric motor that transforms electrical energy—specifically direct current—into mechanical energy by generating a magnetic field. DC motors are at the heart of countless applications, ranging from industrial machinery to consumer electronics, due to their reliability, efficiency, and exceptional speed control capabilities. Understanding how DC motors work, the different types available, and their key benefits can help engineers, procurement teams, and maintenance professionals make informed decisions when selecting the ideal DC motor for their specific requirements.

What is a DC Motor?

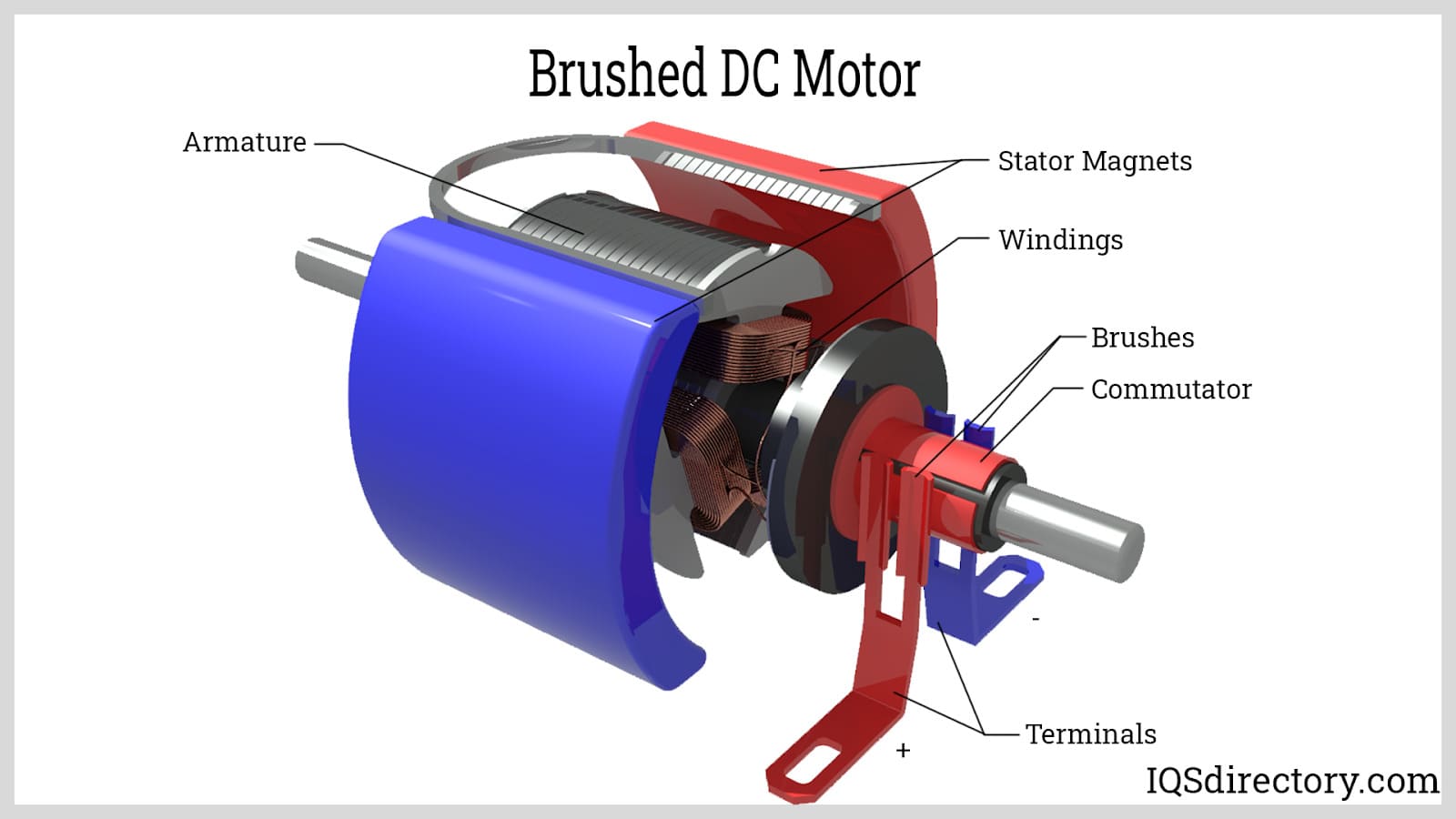

A DC motor is an electromechanical device designed to convert direct current electrical energy into rotational mechanical energy. When electrical power is supplied to the DC motor, it creates a magnetic field in the stator (the stationary part of the machine). This magnetic field interacts with magnets or windings on the rotor (the rotating part), resulting in torque and causing the rotor to spin.

The continuous rotation of the rotor is enabled by a commutator, which—together with brushes—ensures that electrical current is properly supplied to the windings of the motor. This switching mechanism reverses the direction of current flow at precisely the right moments, maintaining the rotation and maximizing efficiency. The precise speed control and variable torque output of DC motors make them a preferred choice for a wide range of automation processes, robotics, transportation systems, and industrial controls.

How Do DC Motors Function?

The fundamental principle behind DC motor operation is that a mechanical force is exerted on a current-carrying conductor placed within a magnetic field—a phenomenon described by Fleming's left-hand rule. This force results in the rotation of the rotor, enabling the motor to perform mechanical work.

DC motors can be controlled over a wide range of speeds by adjusting the supply voltage or altering the current flowing through the windings. This feature gives DC motors a significant advantage in applications demanding precise, variable speed control and high starting torque. In environments where alternating current (AC) is prevalent, AC power can be rectified to DC, allowing DC motors to be utilized even in AC-powered facilities, especially when their torque and speed characteristics are superior to similarly sized AC motors.

Types of DC Motors

DC motors can be classified by several criteria, including how the field winding connects to the armature and whether the motor is brushed or brushless. The configuration of the windings and the method of excitation significantly influence the motor's performance, efficiency, and ideal use cases. Understanding these distinctions is critical for selecting the right DC motor for your needs.

Brushed DC Motor

Brushed DC motors are the traditional form of DC motor, utilizing carbon brushes and a commutator to deliver current to the rotor windings. As the rotor turns, the brushes make contact with different sections of the commutator, reversing the current direction and maintaining continuous rotation.

Brushed DC motors are often categorized into shunt wound (parallel windings) and series wound (series windings) configurations. The commutator acts as an electrical switch, reversing the current and generating steady, rotating torque. While these motors are simple, cost-effective, and provide excellent torque at low speeds, they do require routine maintenance due to brush and commutator wear.

- Advantages: Simple design, low cost, high starting torque, easy speed control

- Drawbacks: Brush wear, regular maintenance, electrical noise

Looking to reduce downtime and maintenance costs? Explore whether switching to a brushless DC motor could benefit your operation.

Brushless DC Motor (BLDC)

Brushless DC motors (BLDC motors) eliminate the need for brushes and commutators by using electronic controllers to switch current in the windings. The rotor is typically constructed with permanent magnets, while the stator contains the winding coils. This design reduces mechanical wear, minimizes maintenance, and allows for higher efficiency and power density.

Brushless DC motors are favored in electric vehicles, drones, robotics, industrial automation, and precise motion control systems. Although initial costs are higher, the increased reliability, lower operating noise, and enhanced energy efficiency make BLDC motors an attractive long-term investment.

- Advantages: High efficiency, low maintenance, extended lifespan, compact design

- Applications: Electric cars, medical devices, computer cooling fans, CNC machinery, automated guided vehicles (AGVs)

Need help integrating brushless motors into your automation systems? Contact our brushless motor suppliers for tailored solutions and expert guidance.

Separately Excited DC Motor

Separately excited DC motors feature field and armature windings powered by independent external sources. This configuration allows for precise control of both field and armature currents, enabling fine-tuned adjustment of speed and torque. Such motors are commonly used in applications where tight torque and speed regulation is critical, such as traction systems, test benches, and experimental setups.

- Advantages: Independent control of field and armature, highly accurate speed regulation, suitable for dynamic loads

- Typical Uses: Laboratory testing, railway traction, industrial automation requiring variable speed and torque

Permanent Magnet DC Motor (PMDC)

Permanent magnet DC motors replace the traditional field winding with high-strength permanent magnets mounted on the stator core. This design reduces weight, size, and cost, while maintaining strong torque characteristics at startup. The armature includes a standard commutator and brush assembly, similar to brushed DC motors.

PMDC motors utilize rare earth magnets such as neodymium or samarium cobalt for enhanced performance. These motors are widely used in battery-powered devices, small appliances, servo mechanisms, and automotive actuators, where compactness and reliability are paramount.

- Advantages: Lightweight, compact, efficient, low cost

- Common Applications: Power tools, portable electronics, small robotics, automotive window lifts

Applications and Uses of DC Motors

DC motors are indispensable across a spectrum of industries due to their unique combination of high starting torque, smooth speed control, and dependable performance. Their adaptability makes them the motor of choice for both heavy-duty industrial equipment and precision electronic systems.

- Industrial Automation: DC motors drive conveyor belts, machine tools, and process control equipment, ensuring precise speed regulation and rapid response to load changes.

- Transportation: Diesel-electric locomotives utilize DC traction motors to convert generator output into mechanical movement. Electric vehicles (EVs) and hybrid systems often rely on high-performance BLDC motors for propulsion and accessory drives.

- Cranes and Hoists: DC motors provide reliable lifting power with the capability to maintain torque at zero speed—ideal where mechanical brakes are minimized.

- Pumps and Fans: Variable speed DC motors are commonly used in pump systems, HVAC fans, and blowers, offering energy savings through precise control.

- Consumer Electronics: Applications include motorized toys, power tools, computer peripherals, and household appliances.

- Medical Devices: DC motors are found in infusion pumps, prosthetics, wheelchairs, and diagnostic equipment, where silent operation and reliability are crucial.

- Robotics and Automation: Both brushed and brushless DC motors power robotic arms, servo systems, and automated guided vehicles (AGVs), enabling precise motion control and rapid response.

Wondering which DC motor type is best for your application? Contact our experts or use our request for quote form for personalized recommendations.

Key Benefits and Advantages of DC Motors

Choosing the right DC motor can deliver a range of tangible benefits for your project or operation. Here are the most significant advantages to consider:

- Precise Speed Control: DC motors allow for seamless adjustment of rotational speed, making them ideal for automation, robotics, and process control.

- High Starting Torque: Essential for applications where loads must be moved from a standstill or require rapid acceleration.

- Simple Control Systems: DC motor controllers are straightforward, reducing complexity and cost in many applications.

- Rapid Response to Load Changes: DC motors adapt quickly to varying load demands, maintaining consistent performance.

- Compact and Lightweight Options: Especially true for permanent magnet and brushless designs, which suit portable and battery-powered devices.

- Reliable and Proven Technology: Decades of use in industrial settings demonstrate the robust performance and longevity of well-designed DC motors.

- Low Maintenance (BLDC & PMDC): Modern brushless and permanent magnet DC motors require minimal servicing, reducing downtime and lifecycle costs.

- Broad Voltage Compatibility: DC motors are available for low voltage (e.g., 12V, 24V, 48V) and high voltage (up to several hundred volts) systems.

How to Choose the Right DC Motor

Selecting the optimal DC motor for your application involves evaluating several key parameters and decision factors:

- Required Torque and Power: Calculate the load torque, desired speed, and total power consumption to match the motor’s performance profile.

- Speed Range: Determine if your application requires constant speed, variable speed, or rapid acceleration/deceleration.

- Voltage and Current Ratings: Ensure compatibility with your system’s power supply and intended operating environment.

- Motor Size and Mounting: Consider available space, mounting configuration, and weight constraints.

- Duty Cycle and Environment: Will the motor run continuously or intermittently? Are there dust, moisture, or temperature extremes to address?

- Maintenance Requirements: Brushless designs minimize servicing, while brushed motors may require periodic brush replacement.

- Budget and Lifecycle Costs: Weigh initial investment against maintenance, energy consumption, and expected lifespan.

DC Motor Control and Drive Systems

To unlock the full performance potential of your DC motor, pairing it with the right motor controller or drive system is essential. Options range from simple manual switches for basic on/off and speed adjustments, to sophisticated electronic speed controllers (ESCs) and programmable logic controllers (PLCs) capable of advanced feedback, protection, and networking.

- Analog Controllers: Simple potentiometer-based speed controls for low-cost, low-complexity applications.

- PWM Controllers: Pulse-width modulation (PWM) provides precise speed, direction, and torque control, minimizing electrical losses.

- Digital Drives: Microcontroller or PLC-based systems offering programmable profiles, real-time feedback, and network integration for industrial automation.

- ESCs (Electronic Speed Controllers): Essential for brushless DC motors, providing commutation and protection functions.

Maintenance and Troubleshooting for DC Motors

Regular inspection and maintenance prolong the service life of DC motors and reduce unexpected downtime. For brushed DC motors, periodic replacement of brushes, cleaning of the commutator, and lubrication of bearings are essential. Brushless DC motors and PMDC motors require minimal maintenance but should be checked for bearing wear and controller health.

- Monitor for unusual noise, vibration, or overheating.

- Inspect electrical connections and insulation resistance.

- Check for dust, debris, or moisture ingress, particularly in harsh environments.

- Validate controller settings and feedback loops for optimal performance.

Choosing the Right Brushless Motor Supplier

For the best results when purchasing a brushless DC motor or any DC motor product, it is crucial to compare multiple suppliers. Our comprehensive directory of brushless motor suppliers provides detailed business profiles highlighting each supplier’s areas of expertise, manufacturing capabilities, certifications, and customer service reputation.

Utilize our proprietary website previewer to explore each brushless motor company’s specialties, product range, and technical resources. When you’re ready, use our streamlined RFQ form to contact multiple brushless motor companies simultaneously. This ensures you receive competitive quotes and expert recommendations tailored to your application.

- Compare supplier experience, quality assurance standards, and delivery times.

- Evaluate after-sales support, technical assistance, and warranty policies.

- Request sample motors or datasheets to confirm performance for your requirements.

Ready to buy or need a custom DC motor solution? Contact our brushless motor experts today for personalized assistance, or browse our brushless motor supplier directory to get started.

Frequently Asked Questions About DC Motors

- What is the difference between brushed and brushless DC motors? Brushed DC motors use carbon brushes and a commutator for current delivery, requiring routine maintenance. Brushless DC motors use electronic commutation and permanent magnets, offering higher efficiency, lower maintenance, and longer lifespan.

- Are DC motors suitable for variable speed applications? Yes. DC motors excel at speed control, making them ideal for applications requiring adjustable or programmable speed profiles.

- Can I use a DC motor with an AC power source? Yes, but you’ll need a rectifier to convert AC to DC before supplying the motor.

- What is the lifespan of a DC motor? With proper maintenance, brushed DC motors can last thousands of hours, while brushless and PMDC motors often exceed 20,000 hours of service life.

Still have questions about DC motors? Ask our motor experts for further learning.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services