AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

Glentek, Inc. is a trusted provider of high-performance electric motors, specializing in innovative motion control solutions for a wide range of industries. We design and manufacture precision servo motors and amplifiers, delivering powerful and efficient performance for demanding applications. Our engineering expertise allows us to develop both standard and custom solutions, ensuring that each...

A leading supplier of high-performance motors and components, Chiaphua Components North America serves customers throughout the Americas and offers electric motors through the CCL & CIM Motor Products division. We supply motor solutions such as brushless motors, permanent magnet DC motors, induction motors, shaded pole motors, universal motors, vacuum cleaner motor, & gear motors.

More Brushless Motor Manufacturers

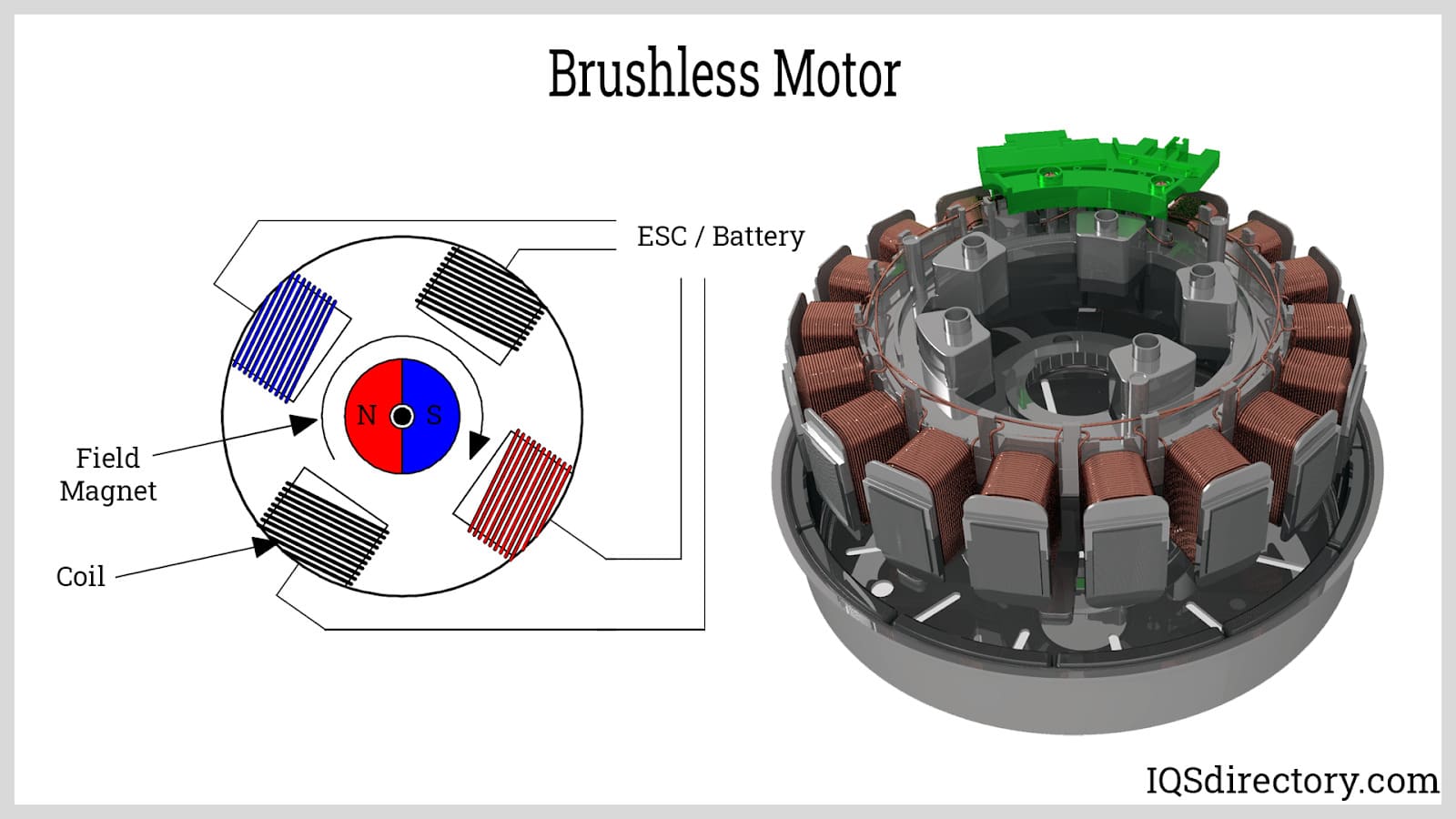

A brushless motor, also known as a brushless DC motor (BLDC motor), is a highly efficient, synchronous motor that operates without mechanical brushes by utilizing a direct current (DC) electrical power supply. With the absence of brushes, these motors offer increased durability, low maintenance, and improved energy efficiency, making them a preferred choice for a wide range of industrial, commercial, and consumer applications that demand reliable and precise motor control.

What Is a Brushless Motor?

A brushless motor, or BLDC motor, is an electric motor that relies on an electronic controller rather than mechanical brushes to regulate current and create the rotating magnetic fields necessary for motion. The motor controller switches DC power to the windings, generating magnetic fields that rotate in space and interact with the rotor’s permanent magnets. This electronic commutation enables high efficiency, accurate speed control, and reduced maintenance compared to traditional brushed motors.

The controller adjusts the phase and amplitude of DC pulses to precisely modulate the motor’s speed and torque. This sophisticated control system replaces the need for a mechanical commutator and brushes, which are commonly used in conventional electric motors. As a result, brushless motors are capable of delivering higher performance, longer lifespan, and enhanced operational stability.

How Does a Brushless Motor Work?

The basic operating principle of a brushless DC motor (BLDC motor) is similar to that of a brushed DC motor. Both rely on electromagnetic induction and internal feedback to produce motion. However, the key distinction lies in the construction and commutation method. A brushless DC motor consists of two main components: the rotor (the rotating element, typically equipped with permanent magnets) and the stator (the stationary part containing the windings/electromagnets).

In a BLDC motor, the permanent magnets are attached to the rotor, while the stator houses the windings. The electronic controller energizes the stator windings in a precise sequence, causing the magnetic fields to rotate and “pull” the rotor along. This process is often managed via sensors (such as Hall effect sensors) or sensorless algorithms that detect the rotor position and adjust commutation accordingly.

High-power transistors and advanced circuitry within the controller are used to activate the electromagnets in the stator, ensuring efficient power delivery and optimal shaft rotation. Because of this advanced DC motor design, brushless DC motors eliminate the need for physical brushes, which are prone to wear and friction.

Advantages of Brushless Motor Technology: The absence of brushes not only minimizes wear and tear but also significantly reduces heat generation, resulting in higher efficiency and lower maintenance requirements. While BLDC motors may have a higher initial cost than brushed motors, their superior performance, reliability, and energy efficiency make them a cost-effective investment in the long run.

Key Benefits of Brushless Motors

- Enhanced Efficiency: Brushless motors convert more electrical energy into mechanical power, reducing energy loss and operating costs.

- Longer Lifespan: Without brushes to wear out, these motors can operate reliably for tens of thousands of hours.

- Low Maintenance: Fewer moving parts mean less servicing and downtime.

- High Power Density: Compact design allows for more power in a smaller package, ideal for space-constrained applications.

- Precise Control: Electronic speed controllers enable accurate speed and torque regulation, supporting advanced automation and robotics.

- Quiet Operation: Reduced mechanical friction ensures smooth and silent performance, critical in medical, office, and household devices.

- High Reliability: Exceptional thermal management and robust construction ensure dependable operation in demanding environments.

Types of Brushless Motors

Brushless motors come in several types, each engineered for specific use cases and performance requirements. The main categories include:

Inner Rotor Brushless Motor Design

In an inner rotor brushless motor, the rotor with permanent magnets is positioned at the center, surrounded by the stator windings. This configuration allows for efficient heat dissipation, as the stator (which generates the most heat) is located near the external surface, enabling effective thermal management.

Inner rotor motors are valued for their high torque density and exceptional dynamic performance, making them ideal for applications that require rapid acceleration and deceleration, such as robotics, CNC machinery, and automation systems. The compact rotor diameter and low moment of inertia contribute to their excellent responsiveness.

Typical applications: Industrial servo drives, electric vehicles, precision manufacturing equipment, and high-speed automation.

Looking for maximum power in a compact package? Consider inner rotor brushless motors for demanding industrial and automation tasks.

Outer Rotor Brushless Motor Design

In an outer rotor brushless motor, the stator windings are fixed at the core, while the rotor with permanent magnets surrounds the stator. This design results in a larger rotor diameter and a higher moment of inertia, which provides excellent speed stability and smooth operation at lower speeds.

Outer rotor motors are commonly used in applications where consistent speed and high torque at lower RPMs are essential, such as in ceiling fans, drones, e-bikes, and HVAC blowers. The large rotor diameter also allows for more magnets and magnetic poles, enabling greater output power in a relatively compact design.

Key advantages: Low cogging torque, stable operation, and suitability for high-pole-count, low-speed applications.

Need stable, quiet power for your device? Explore outer rotor brushless motors for fans, model aircraft, and electric transportation solutions.

Disk Rotor (Flat) Brushless Motors

The disk rotor brushless motor, sometimes called a flat or pancake motor, features a stator with windings and magnetic pole sensors mounted on a flat circuit board. The rotor, often a thin disk with surface-mounted permanent magnets, faces the stator. This configuration results in a motor with a very low profile, ideal for space-constrained applications.

Disk rotor motors are preferred in devices that require stable, fixed-speed operation under light loads, such as DVD drives, computer hard drives, and precision medical instruments. Their lightweight, thin design makes them suitable for applications where every millimeter of space counts.

Best suited for: Data storage devices, slim-profile fans, and specialized medical or laboratory equipment.

Curious about flat motor solutions for compact devices? Discover how disk rotor brushless motors can optimize your next electronics project.

Common Applications and Industries Using Brushless Motors

The broad adoption of brushless DC motors (BLDC motors) across industries is driven by their unmatched efficiency, reliability, and versatility. Here are some of the most prominent application areas:

- Consumer Electronics: Cooling fans in computers and laptops, DVD and Blu-ray drives, hard disk drives, and precision scanners.

- Industrial Automation: Robotics, CNC machines, conveyor systems, servo drives, and factory automation.

- Automotive: Electric vehicles (EVs), hybrid vehicles, power steering, electronic throttles, and cooling pumps.

- Medical Devices: Surgical tools, ventilators, infusion pumps, and laboratory automation equipment.

- Power Tools: Cordless drills, saws, grinders, and other battery-powered tools where efficiency and longevity matter.

- HVAC and Appliances: Refrigeration compressors, air conditioning fans, washing machine motors, and vacuum cleaners.

- RC and Drones: Model aircraft, quadcopters, and UAVs that demand lightweight, high-torque, and responsive motors.

- Renewable Energy: Wind turbine pitch control, solar tracking systems, and energy storage solutions.

Which industries benefit most from brushless motors? The answer is broad—with nearly every sector turning to BLDC motors to boost efficiency, precision, and overall product lifespan.

How to Choose the Best Brushless Motor for Your Application

Selecting the ideal brushless motor for your project involves considering several key decision factors. By understanding your application requirements and comparing BLDC motor specifications, you can ensure optimal performance and return on investment.

Key Factors to Consider:

- Required Torque and Speed: Match the motor’s rated torque and maximum RPM to your application’s demands.

- Voltage and Current Ratings: Ensure compatibility with your power supply and controller.

- Size and Weight Constraints: Choose a motor that fits your device or machinery’s physical envelope.

- Control Features: Consider if you need simple on/off control or advanced features like feedback, speed regulation, and torque control.

- Thermal Management: Assess cooling needs, especially in high-duty-cycle or enclosed environments.

- Environmental Conditions: Factor in exposure to moisture, dust, vibration, or extreme temperatures.

- Cost and Availability: Balance upfront investment with long-term reliability and operating costs.

Comparing Brushless Motors vs. Brushed Motors

If you’re evaluating whether to upgrade from brushed to brushless motors, it’s important to understand the differences and advantages in real-world scenarios. While both types have their place, brushless motors are increasingly favored for their superior performance in demanding environments.

| Feature | Brushed Motor | Brushless Motor (BLDC) |

|---|---|---|

| Commutation Method | Mechanical (brushes/commutator) | Electronic (controller) |

| Maintenance | High (brush replacement) | Low (minimal wear parts) |

| Efficiency | Moderate | High |

| Noise | Higher (brush friction) | Quieter (less friction) |

| Lifespan | Shorter | Longer |

| Cost | Lower upfront | Higher upfront, lower total cost of ownership |

| Control Precision | Basic | Advanced |

Ready to make the switch? Explore the latest brushless motor technologies and find trusted suppliers for your upgrade or new design.

Frequently Asked Questions about Brushless Motors

What is the typical lifespan of a brushless DC motor?

Thanks to the absence of brushes and reduced friction, brushless DC motors can often exceed 20,000 to 50,000 operating hours, depending on application and environment. Some industrial-grade BLDC motors are rated for even longer lifespans with proper maintenance and thermal management.

Are brushless motors more energy efficient than brushed motors?

Yes, brushless motors are typically 10-30% more efficient than brushed motors, converting more of the input electrical power into mechanical output. This efficiency translates into lower energy costs, less heat generation, and smaller power supply requirements.

What kind of controller is needed for a brushless motor?

A brushless motor requires a dedicated electronic speed controller (ESC) or BLDC controller that can modulate voltage, current, and phase timing. Controllers can range from simple, open-loop designs to sophisticated, sensor-based feedback systems for advanced applications.

Can brushless motors replace all types of brushed motors?

While brushless motors offer many advantages, some simple or low-cost applications may still use brushed motors for their simplicity. However, for high-performance, high-efficiency, and maintenance-critical applications, BLDC motors are increasingly the preferred solution.

What are the main decision criteria when sourcing a brushless motor supplier?

Key factors include supplier experience, product range, technical support, compliance with industry standards (such as ISO or CE), customization capabilities, and after-sales service. It’s also important to review datasheets, case studies, and customer reviews to ensure the supplier can meet your specific requirements.

Choosing the Right Brushless Motor Supplier

For the best results when sourcing a brushless motor, it’s crucial to compare multiple suppliers and assess their expertise, product quality, and support offerings. Our directory of brushless motor suppliers enables you to review detailed business profiles highlighting each company’s experience, capabilities, product lines, and industry focus.

To streamline your purchasing process, each supplier listing includes a direct contact form. You can easily request more information, technical documentation, or a personalized quote. For a side-by-side comparison, use our proprietary website previewer to understand each company’s specialization and market strengths. Additionally, our unified RFQ (Request For Quote) form allows you to reach out to multiple brushless motor suppliers with a single submission, saving you time and effort.

Optimize your sourcing strategy: Compare technical specifications, lead times, certifications, and customer service levels to ensure you partner with a supplier who can meet your application’s performance and quality demands.

Ready to take the next step? Visit our Brushless Motor Manufacturers Directory to connect with leading suppliers, download datasheets, and start your project today.

Further Reading and Resources

- DC Motors: Types, Applications, and Suppliers

- Servo Motors Explained

- AC Motors and Their Industrial Uses

Still have questions about brushless motors? Contact our team of electric motor experts for personalized advice, application engineering support, or a custom quote.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services