AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

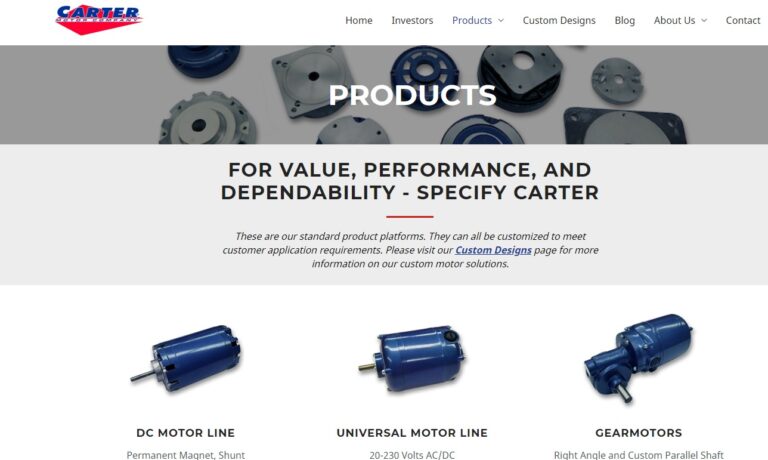

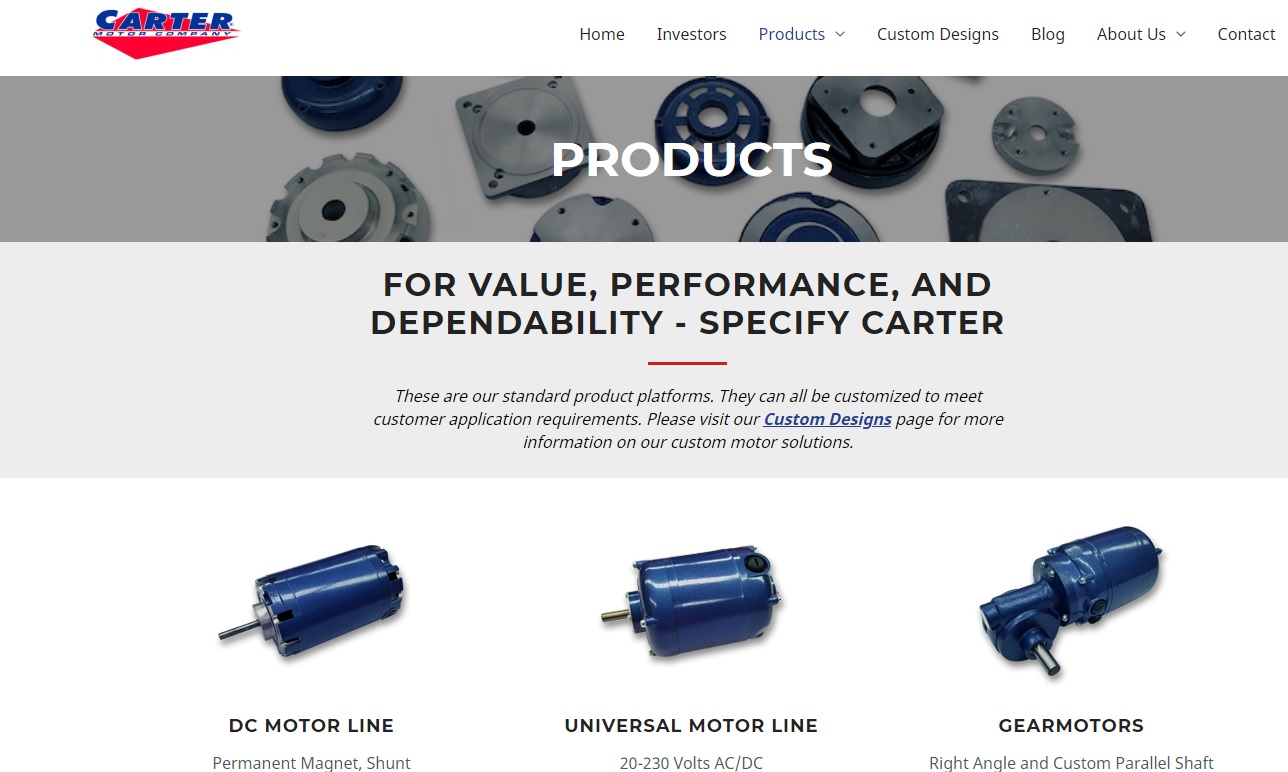

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

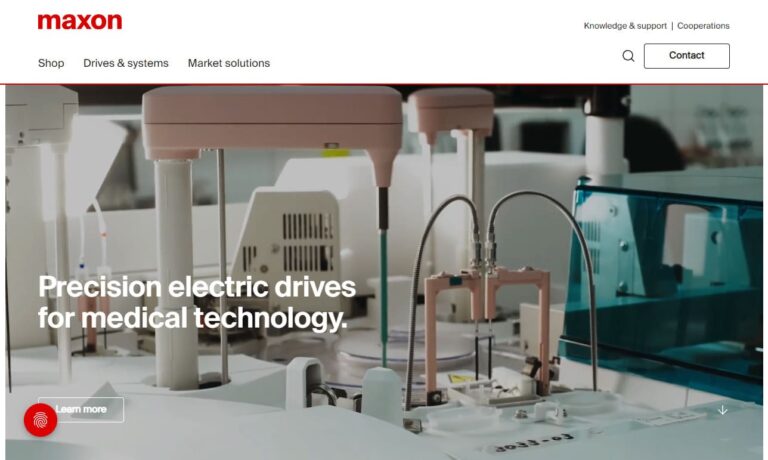

maxon manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control electronics to complement its...

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the electric motor market in innovation & advanced quality assurance. Our AC motors, DC motors & gearheads are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE.

More 1 Horsepower Electric Motor Manufacturers

The name originates in the mid-1800's, when a man named James Scott used the term in his marketing of steam engines, to help people understand the engine's power when compared to draft horses, a commonly understood measure of energy during that time.

This terminology has lasted to modern times, when most modern cars have between 125 and 200 horsepower, while high performance cars have a force potential of 400 horsepower or more. One horsepower electric motors are usually used to power slow moving vehicles like tractors and other agricultural equipment, and high power tools and appliances, like table saws and pool pumps.

In addition to horsepower, electrical, mechanical and performance characteristics help decide the application options of electric motors. Variable electrical characteristics of 1 HP electric motors include: base speed, standard voltage, phase/base frequency (Hz), service factor, design code from NEMA, insulation class, insulation system, duty cycle and thermal protection.

Likewise, variable mechanical characteristics include: mounting frame size, enclosure, frame material, end bracket material, junction box material, fan guard material, lead determination, standard mounting, drive end shaft slinger, paint, bearings, grease and standard junction box assembly position. Frame material is generally a type or grade of steel, such as rolled steel or 304 stainless steel.

End bracket material has a few more options, including aluminum, cast iron and 304 stainless steel. Junction boxes and fan guards may both be made of steel or 304 stainless steel. Finally, fan material may be plastic, polypropylene plastic or heat-resistant polyethylene.

Examples of standard mounting options include: c-face with a removable base, rigid, c-face with a removable rigid base, c-face with a rigid base and c-face with round body. Bearings of 1 HP electric motors are usually ball bearings and grease options may include Mobil Polyrex EM and Korschun lithium-based.

Variable performance characteristics include: constant torque speed range, variable torque speed range, constant horsepower speed range, temperature rise and encoder provisions.

One HP electric motors have many applications in gas and oil and mining, agriculture and agribusiness, water and wastewater, aggregate and cement, food and beverage, pharmaceutical and pulp and paper industries. One HP electric motors are able to reach all of these markets through the strength of their low-voltage capabilities.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

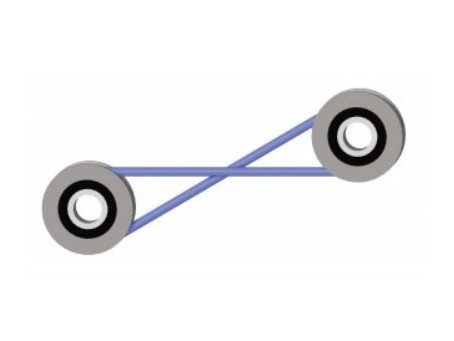

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services