We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

For custom-designed and -manufactured gear motors, contact us. We’ve been doing this business since 1958. So, for either permanent magnet AC motors or shaded pole induction DC motors, we’re the ones to get in touch with. Our website contains a downloadable motor design sheet—we welcome you to use it.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

American Electric Motors is a full service shop offering total sales & repair service, from A.C. motors, pump motors & servo motors to 5,000 H.P. D.C. motors. We stock & sell all types of new motors, pumps & brakes, plus our large inventory of used & remanufactured electric motors can save you thousands.

Connect With Recommended Electric Motor Suppliers

Provide us with your project specifications, and we’ll connect you with our network of qualified plating & coating suppliers who can give you a free proposal. Our team has been manually sourcing and curating the best U.S. manufacturers for over 20 years.

Request for QuoteWe're the #1 destination for finding U.S. Manufacturers

More Single Phase Motor Manufacturers

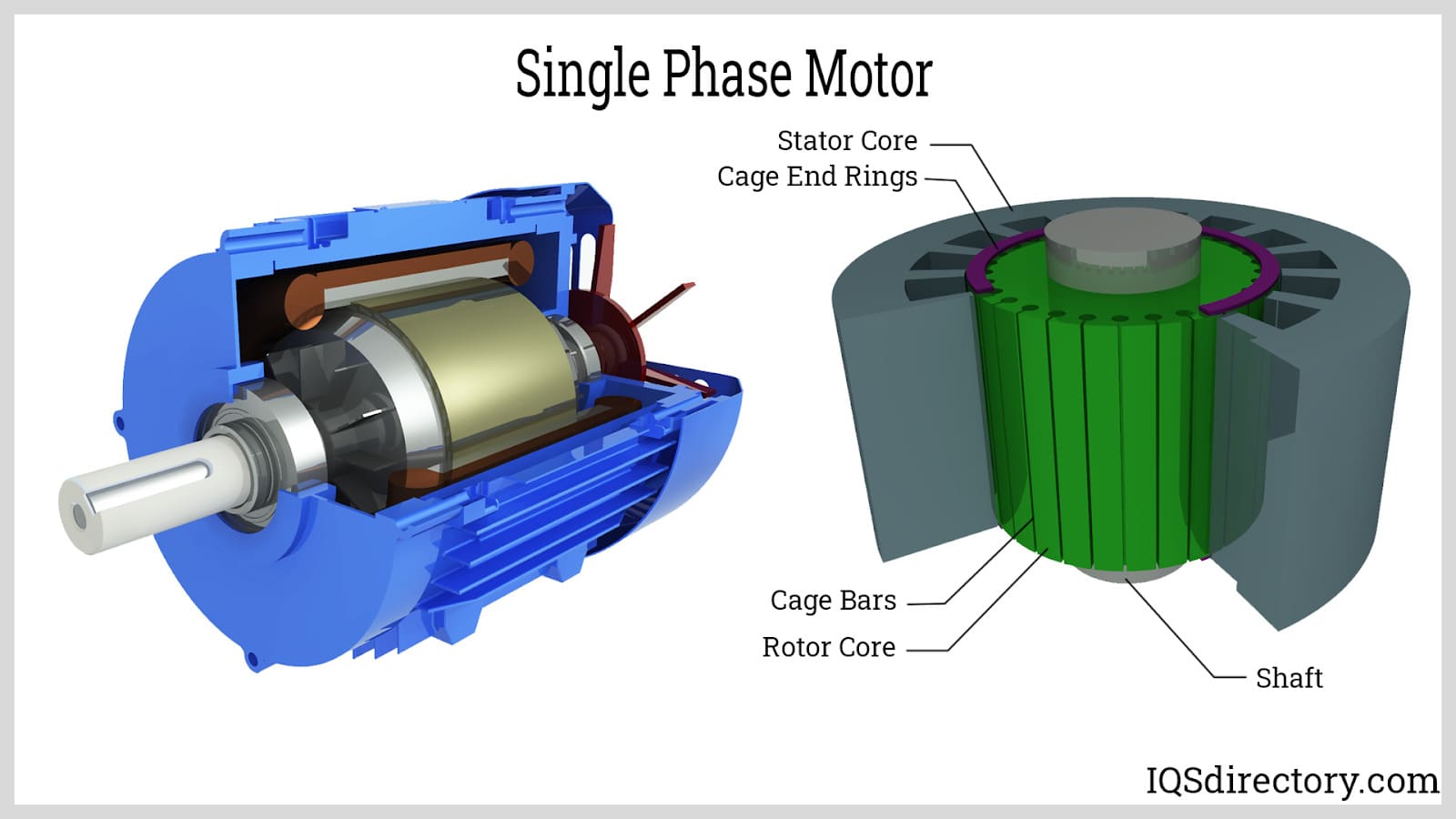

A single-phase motor is a rotary machine that is electrically powered and can turn electric energy into mechanical energy. The single-phase motor works by using a single-phase power supply, and it contains two types of wiring, hot and neutral.

What is a Single-Phase Motor?

A single-phase motor’s power can reach 3KW, and its supply voltages vary in unison. They also have a single alternating voltage, and its circuit works with two wires as the contained current that runs across them is always the same. These types of motors do not generate a rotating magnetic field as they can only generate an alternate field, and because of this, they require a capacitor for a startup.

How a Single Phase Motor Functions

A single-phase AC supply is brought to the main winding, which is the stator winding. The alternating current flowing through the main winding produces a magnetic flux known as the main flux. The rotor is now assumed to be rotating and placed in a magnetic field produced by the stator winding. Based on Faraday’s Law, the current begins to flow in the rotor circuit, which is a closed path. This flowing current is known as rotor current. This rotor current results in the flux being produced around the rotor winding, which is called the rotor flux.

From the interaction between the main and the rotor flux, a torque is produced in the rotor and results in the rotor’s rotation. The stator’s field is alternating in nature and is the same as synchronous speed. This synchronous speed of the DC motor depends on the number of poles and the supply frequency. The interaction between the rotor flux and the stator flux, which results in the rotation of the motor, can be contained in a theory called the Double Revolving Theory.

Types of Single Phase Motors

The single-phase induction motors can be classified in accordance with the starting methods. Some classes include split phase induction motor, shaded pole induction motor, permanent capacitor induction motor, and capacitor start induction motor.

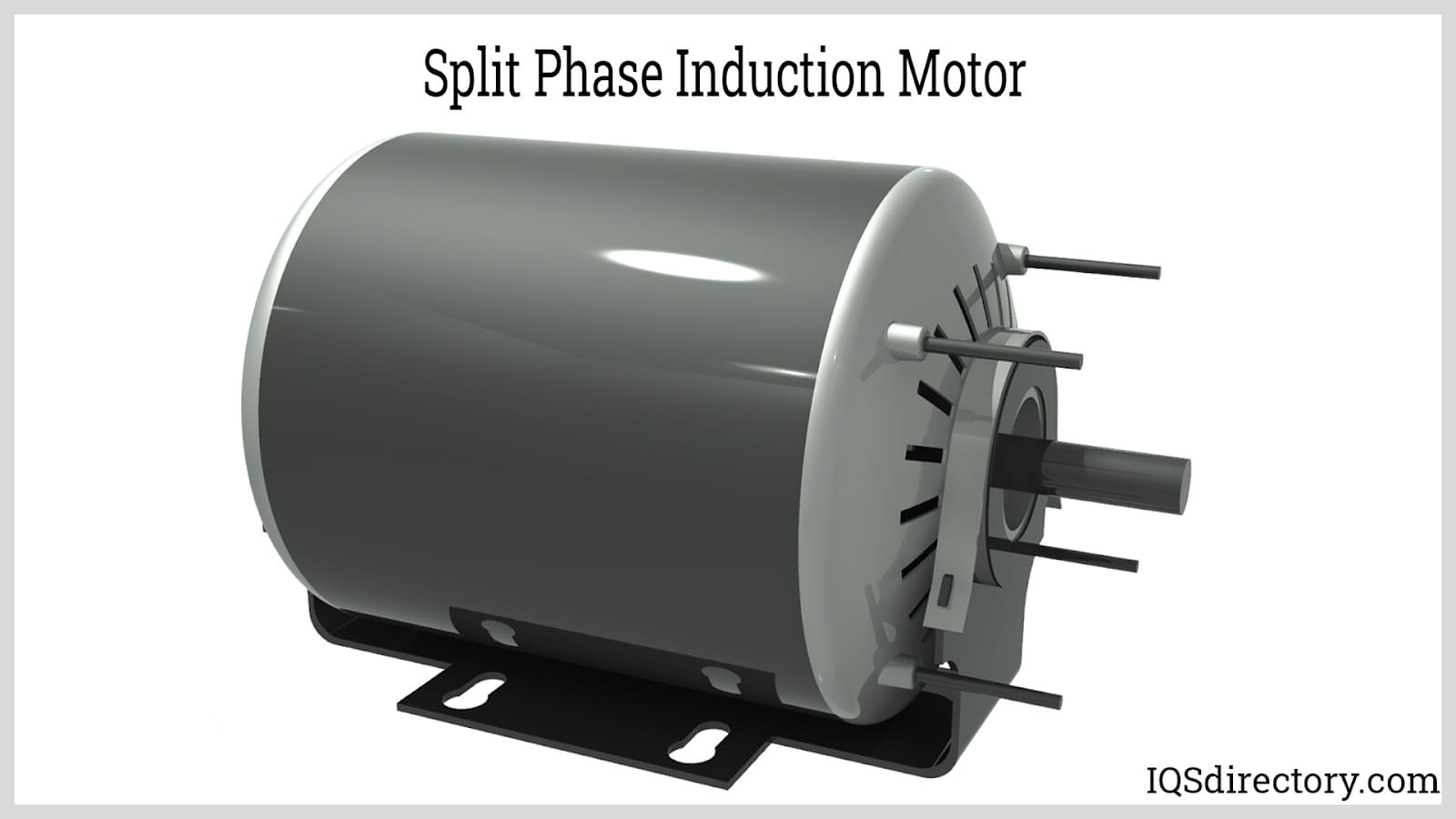

Split Phase Induction Motor

This type of motor contains an extra winding that is wound on the same core of the stator. So in total, there are two windings on the stator. The windings are known as the main winding and the starting winding. The starting winding, also called the auxiliary winding, contains a centrifugal switch connected in series with it. This starting winding is highly resistive, and the main winding is highly inductive. The starting winding contains a few turns and also a small diameter. The major aim of the auxiliary winding is to create a phase difference between the two fluxes, which are produced by the rotor winding or the main winding.

Permanent Capacitor Induction Motor

This low-value capacitor is connected constantly with the starting winding. As a result, the capacitor has low capacitance. The permanent capacitor is put into use in increasing the starting torque, but it is low as compared to the capacitor start induction motor. There is a very high magnitude in this motor’s power factor and efficiency. At the same time, it has a very high starting torque, ranked at 80% of the full load torque.

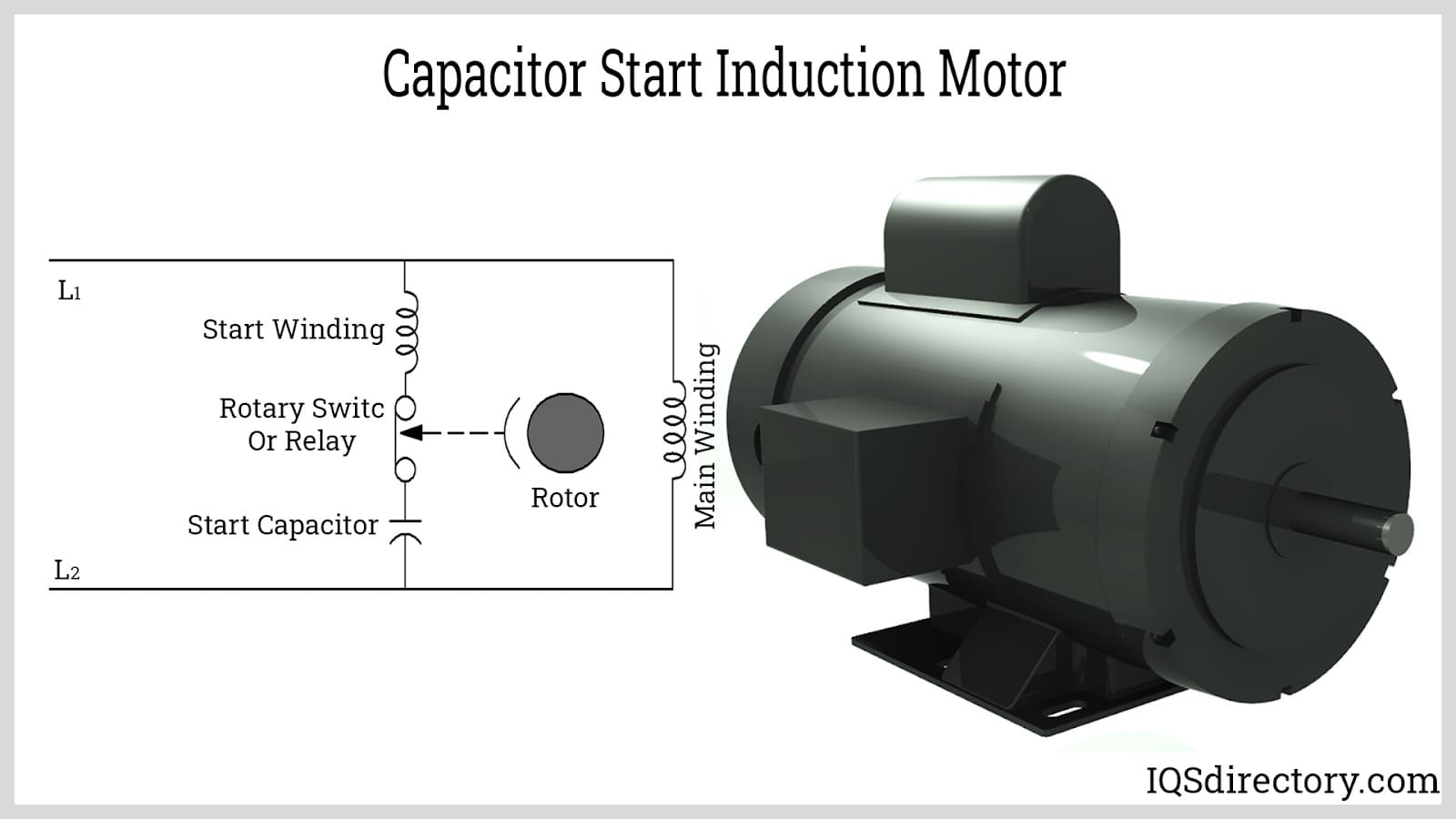

Capacitor Start Induction Motor

This type of motor is a modified advanced version of the split phase induction motor. The disadvantage of the split phase induction motor is low torque production because the phase difference produced in this motor is very less. This disadvantage is compensated with the help of a capacitor connected in a series with the auxiliary winding. The capacitor contained in this motor is a dry type capacitor designed to use alternating current.

Despite this, the motor is not used for continuous operation. Here a centrifugal switch is also used, disconnecting the capacitor and the auxiliary winding when the motor runs at a range of 75% to 80% of the synchronous speed.

Applications and Uses of Single Phase Motors

For excellent efficiency, single-phase motors are used in refrigerators, freezers, and heaters. Because of form utility, the motors come in different variations of 0.5HP to 15HP. They are also used in home equipment and devices such as clocks, washing machines, grinding machines, and computers.

Choosing the Proper Single-Phase Motor Manufacturer

To ensure you have the most constructive outcome when purchasing a single-phase motor from a single-phase manufacturer, it is important to compare several companies using our directory of single-phase manufacturers. Each single-phase manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each single-phase motor company website using our patented website previewer to get an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple single-phase companies with the same form.

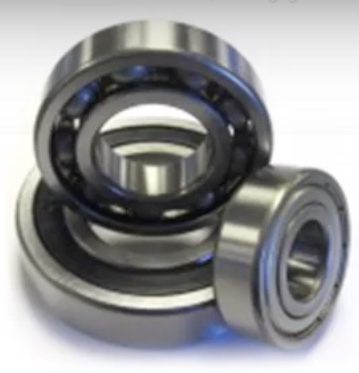

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

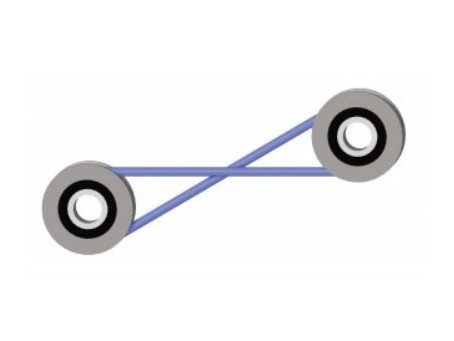

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services