AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

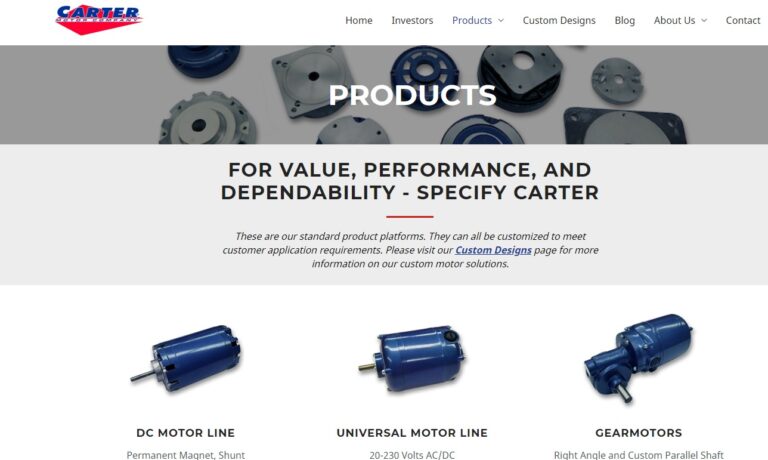

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

maxon manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control electronics to complement its...

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the electric motor market in innovation & advanced quality assurance. Our AC motors, DC motors & gearheads are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE.

More DC Motor Manufacturers

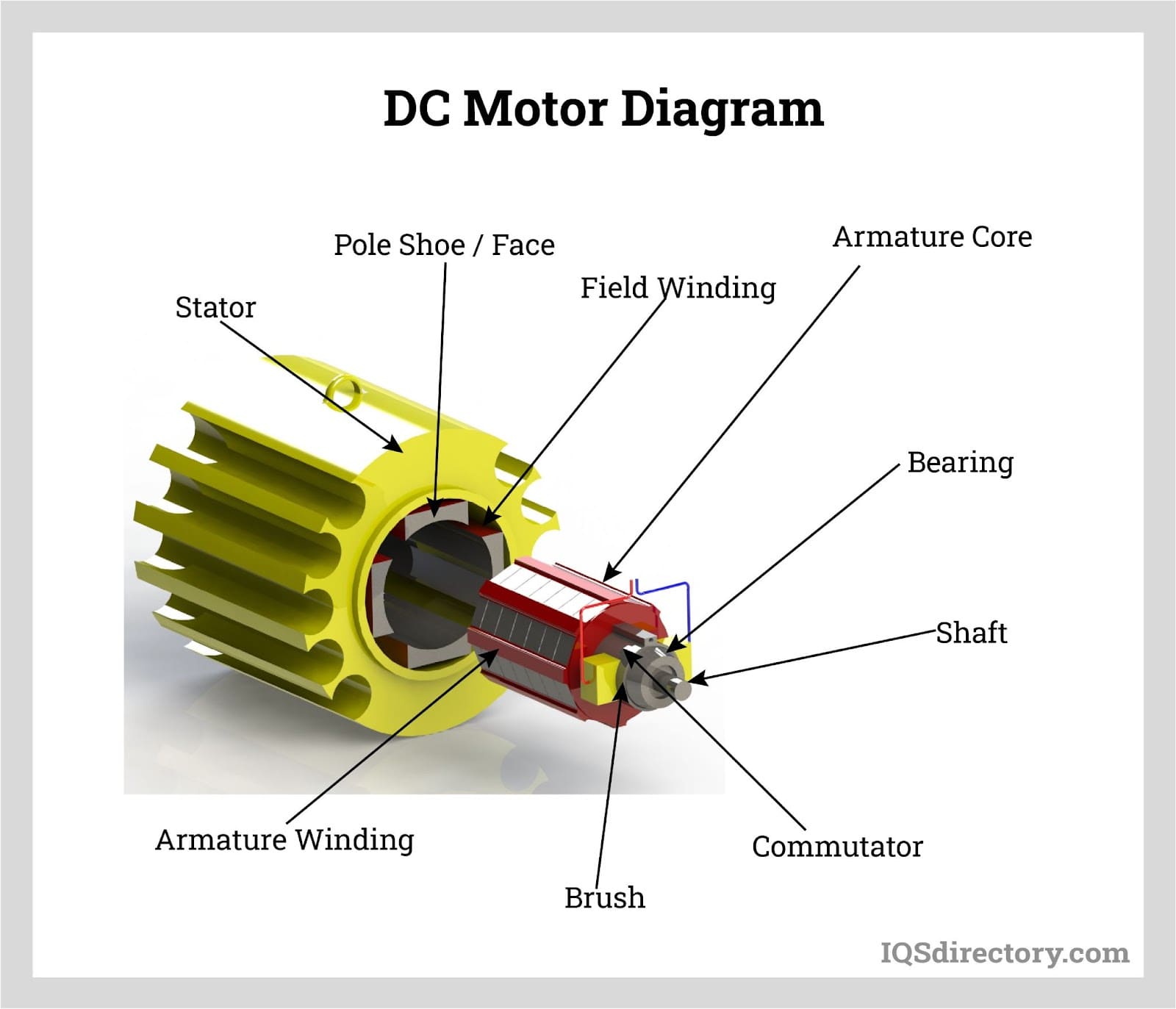

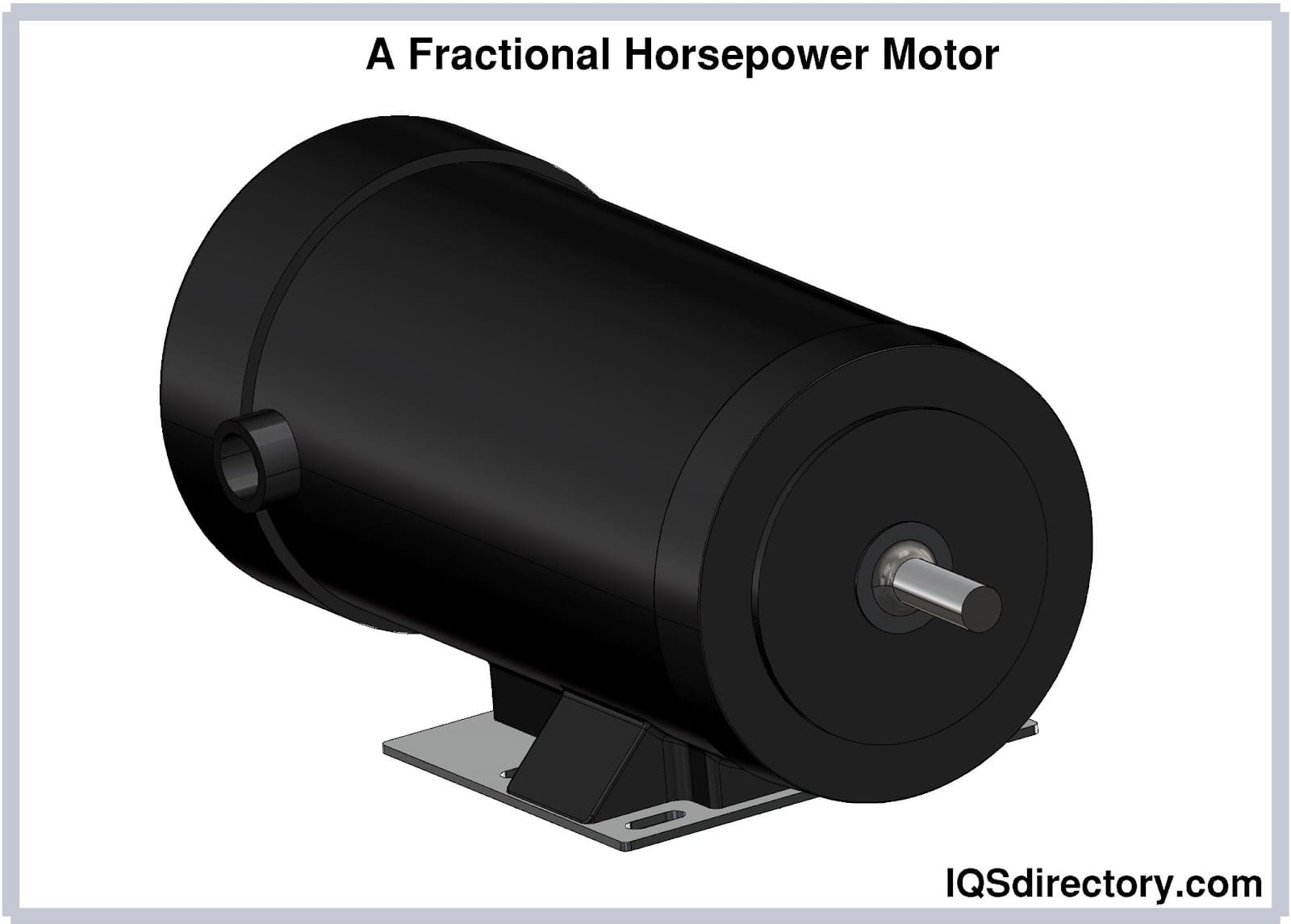

A direct current (DC) motor is an electrical machine that transforms electrical energy into mechanical energy by creating a magnetic field powered by a direct current.

What is a DC Motor?

When the DC motor is powered, a magnetic field is created in the stator. The magnetic field attracts and repels magnets on the rotor, which results in the rotor's rotation. For the rotor's continuous rotation, the commutator attached to brushes connected to the power source supplies current to the wire winding of the direct current motor. DC motors are preferred for industrial machinery because of their ability to control their speed with higher precision.

How DC Motors Function

DC motors work based on the idea that mechanical force is produced when a current-carrying conductor is placed in a magnetic field. The direction of this result can be determined using the left-hand rule. Using a variable supply voltage or changing the strength of the current in the motor's windings, we can control the contained speed over a wide range. For bigger areas of use, alternating current (AC) is changed into DC because a DC motor's torque and speed characteristics are superior to an AC motor.

Types of DC Motors

DC motors can be differentiated by the connections between the field winding and the armature. This field winding can be connected parallel to the armature or inserted in a series manner. In some cases, the connection is both. The DC motors can also be differentiated by how the rotor is powered, as they can be brushed or brushless.

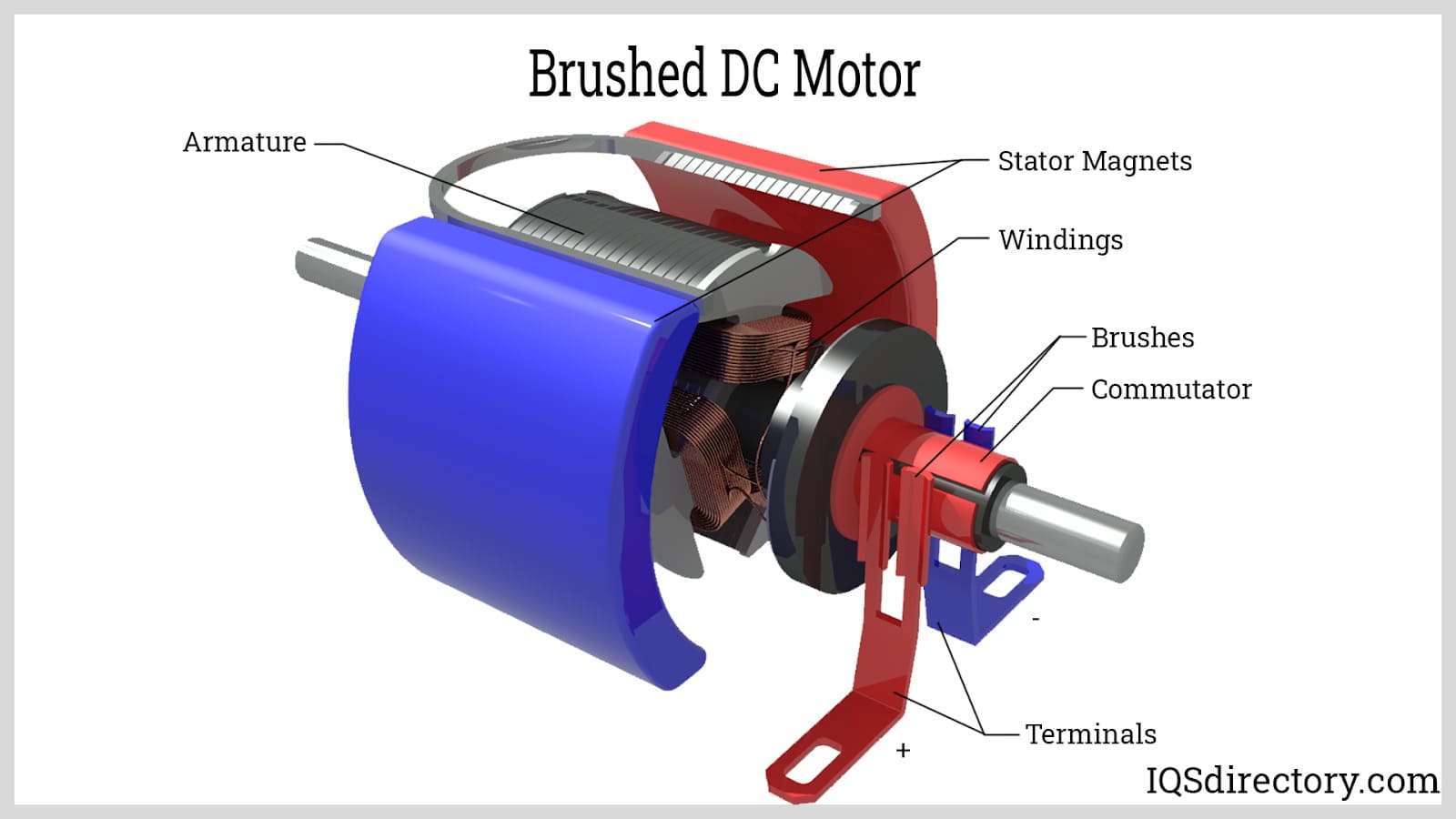

Brushed DC Motor

In brushed DC motors, the current is applied by brushes, and the magnetic field is produced by the current sent through the commutator and brushes connected to the rotor. The brushes are made of carbon, which can be separately excited or self-excited. The contained stator is the enclosure that contains the part of the motor and the magnetic field.

The winding of the coil on the rotor can be in a series or parallel to form either a shunt wound DC motor or a series wound DC motor. The commutator is the electrical switch that reverses the current between the rotor and the external power source. This method applies electrical current to the windings and produces a steady, rotating torque by reversing the direction of the current.

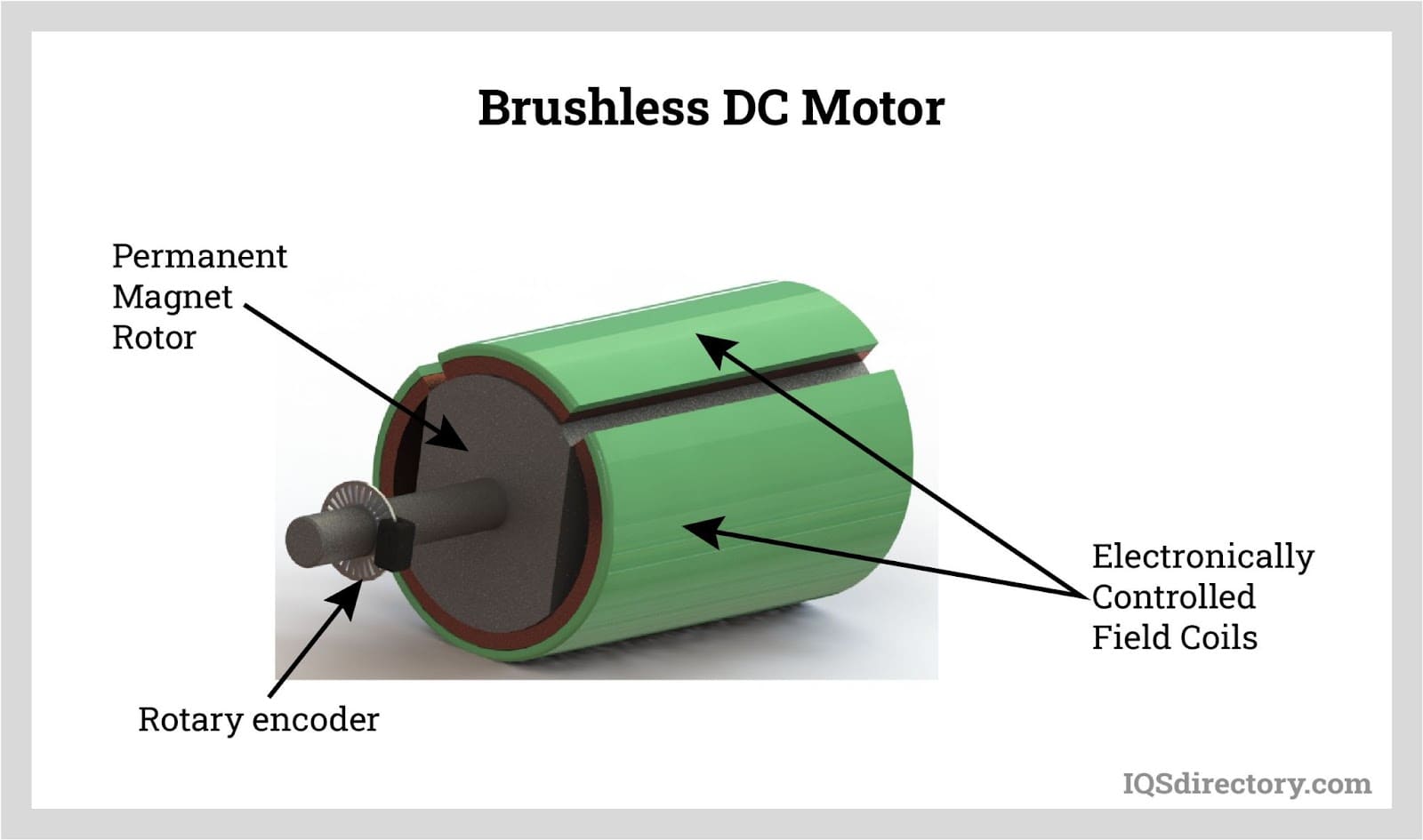

Brushless DC Motor

This type of motor contains a permanent magnet rotor and a coil wound stator. Because of this DC motor design, there is no need for brushes. The advantage of a brushless DC motor is the removal of tear and wear of the brushes since very little heat will result from the rotating magnet. Brushless DC motors are more expensive because of their efficiency.

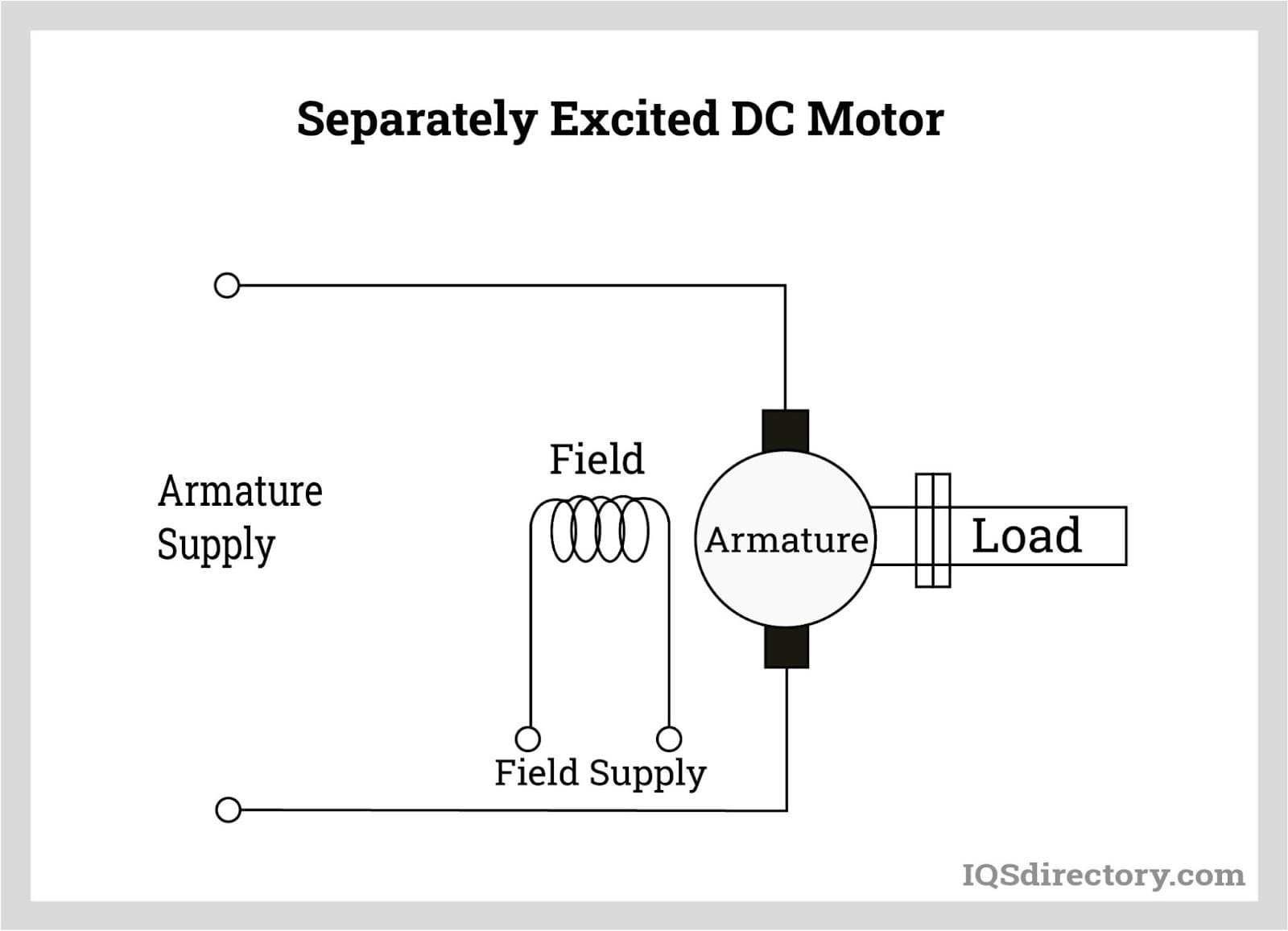

Separately Excited DC Motor

In this type of DC motor, the contained motor has separate electrical supplies for the armature winding and field winding, which are electrically separate from each other. The functions of the armature current and the field current do not interfere with each other, but the input power is their total sum.

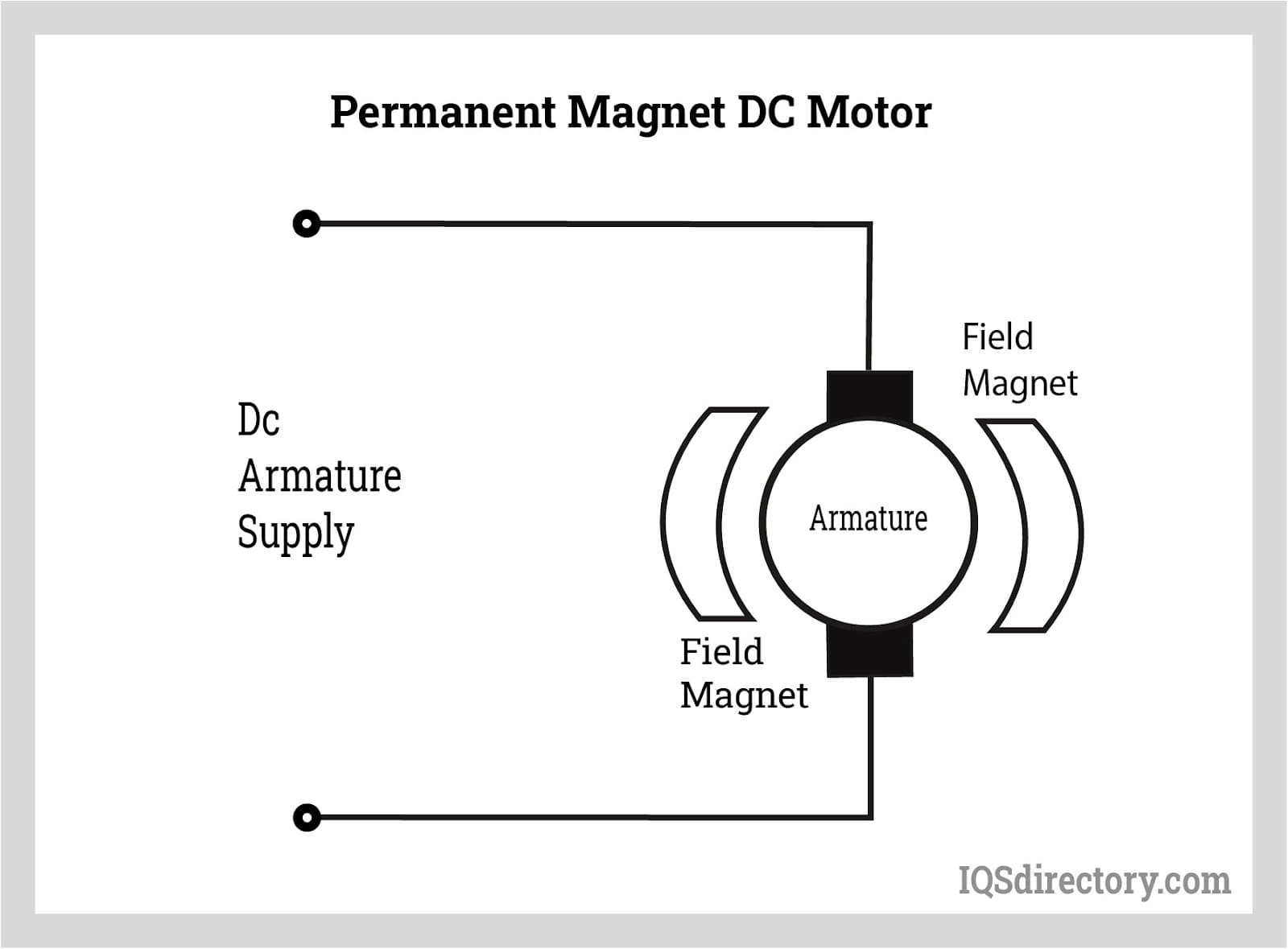

Permanent Magnet DC Motor

This DC motor contains an armature winding but does not contain a field winding. Instead, it has a permanent magnet mounted on the stator core's inner surface to produce the magnetic field. The armature is regular, and it consists of a commutator and brushes. The permanent magnet DC motor is smaller in size and is less expensive. In their operation, they use rare earth magnets such as samarium cobalt.

Applications and Uses of DC Motors

DC motors are used in diesel-electric locomotives. The electrical energy converted by a generator in the diesel-electric locomotive from rotational energy is supplied to DC motors connected to the wheels on the engine. In use in cranes, it is ideal for the motor to have the ability to hold a full zero speed where mechanical brakes may not be needed. In electric vehicles, brushed DC motors retract and position electrically powered windows. DC motors are used in pumps because they have variable speed control, high starting torque, good transient response, and a simple control system.

Choosing the Right Brushless Motor Supplier

For the most positive outcome when purchasing a brushless motor from a brushless motor supplier, it is important to compare several companies using our directory of brushless motor suppliers. Each brushless motor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each brushless motor company website using our proprietary website previewer for an understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple brushless motor companies with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services