AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

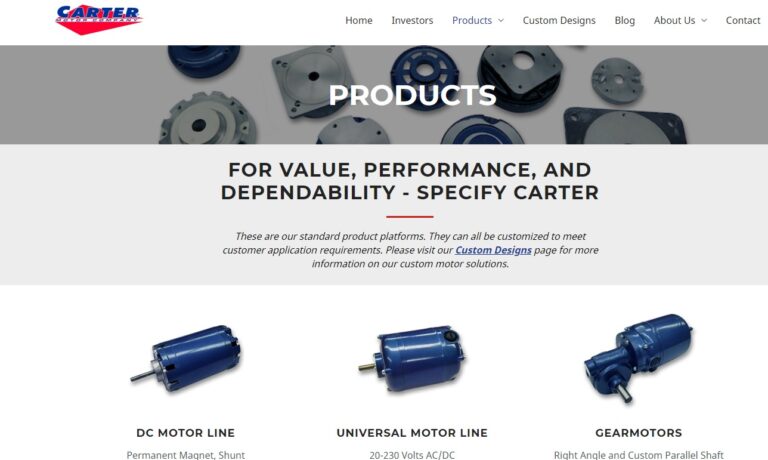

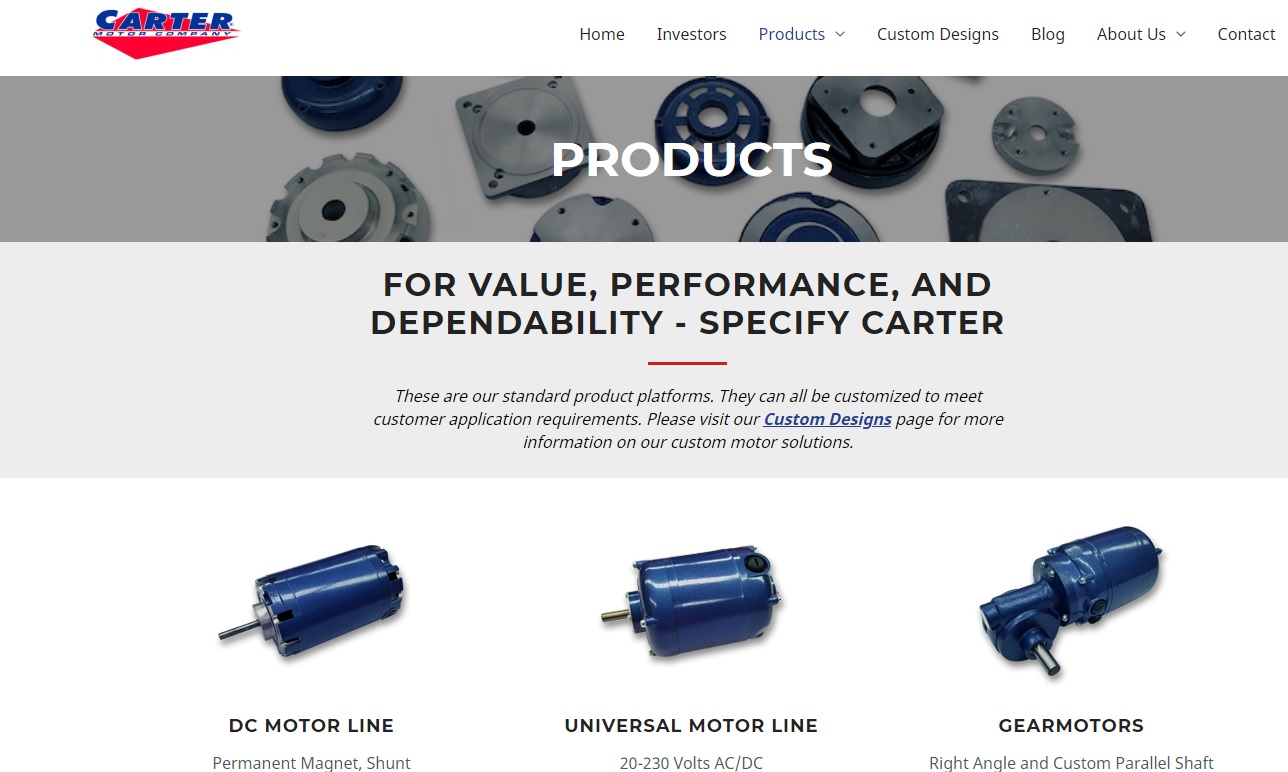

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

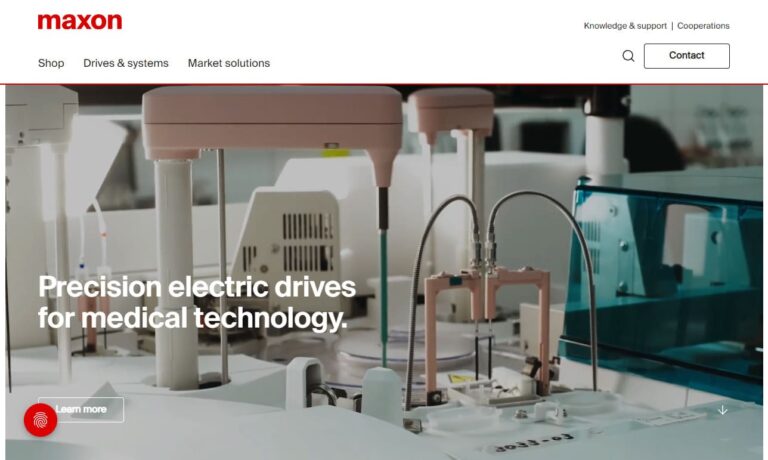

maxon manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control electronics to complement its...

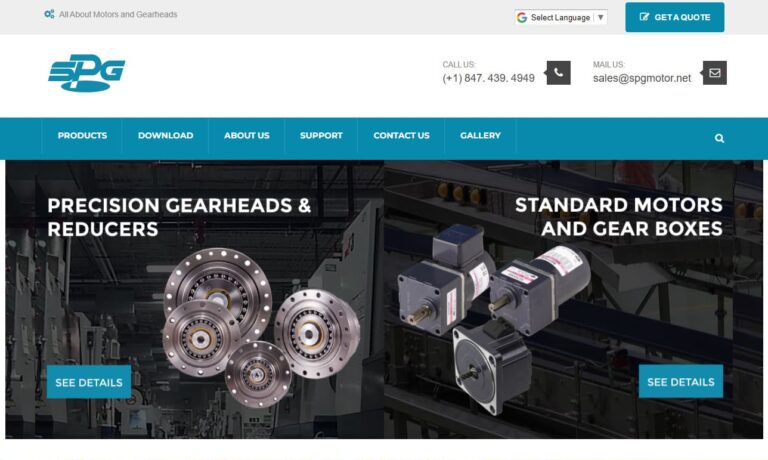

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the electric motor market in innovation & advanced quality assurance. Our AC motors, DC motors & gearheads are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE.

More Industrial Motor Manufacturers

Industrial motors come in a wide range of horsepower, base speeds, voltage ratings, variable speed range and motor efficiency.

Industrial motors vary in enclosure types, insulation systems, frame construction, encoder capabilities, or lack thereof, and the environments in which they can be used. Industrial motors touch many industries, including gas and oil, mining, agriculture and agribusiness, water and wastewater, pulp and paper, aerospace, food and beverage, military and defense, material handling and transportation and utilities.

Industrial motors are widely categorized into two categories: DC motors and AC motors. DC motors, which operate with a direct current, are less commonly used for industrial purposes, as they are an older, less independent technology. However, when coupled with a DC drive, they provide very precise control. They have two major advantages as industrial motors.

First, it is easy to control their speed in a wide range; historically their torque characteristics have been easier to customize than AC motors. Second, their reduced overall dimensions allow for a significant saving of physical space on the plant floor. DC motors, however, do have several disadvantages.

One of the disadvantages of brush DC motors is the fact that they need brushes to connect to the rotor winding. In addition to the added cost, brushes wear quickly, especially in low-pressure environments. DC motors thus cannot be used on aircrafts. Also, if its working environment contains explosive materials, sparks from the brushes could prompt an explosion.

However, many manufacturers make brushless DC motors to remedy some of these issues. They work well as industrial motors for conveyors, elevators, extruders, material handling, paper, plastics, rubber, steel and textile applications, automobile, aircraft, portable electronics and all speed control applications.

AC, or alternating current, motors are far more widely used as industrial motors. General advantages of the AC motor include: simple design, low cost, reliable operation, variety of mounting styles, the fact that replacement parts are easily found and the fact that they have many different environmental enclosures.

In fact, its simple design is the main reason that they are overwhelmingly preferred for industrial applications. Their disadvantages include: expensive speed control, poor positioning control and an inability to operate at low speeds. AC motors are found in air conditioners, washers, dryers, industrial machinery, fans, blowers, vacuum cleaners and more.

In their breadth, the applications of industrial motors are extremely diverse, from industrial pumps to disc drives, and their power sources are extremely diverse as well. Their DC power sources include batteries, motor vehicles and rectifiers, while their AC power sources may be power grids, inverters or generators.

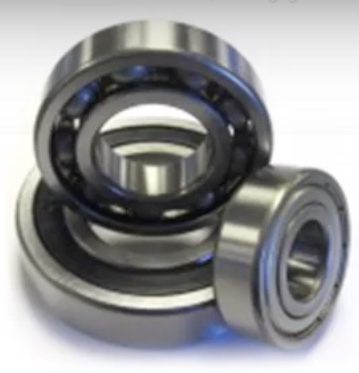

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

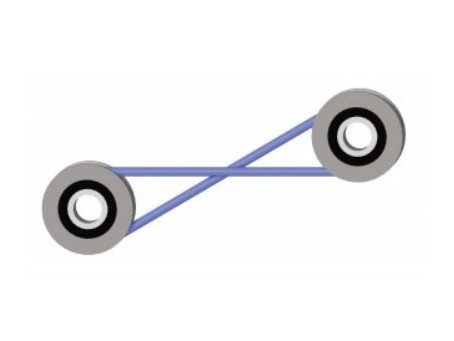

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services