AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

maxon manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control electronics to complement its...

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the electric motor market in innovation & advanced quality assurance. Our AC motors, DC motors & gearheads are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE.

More Brushless Motor Manufacturers

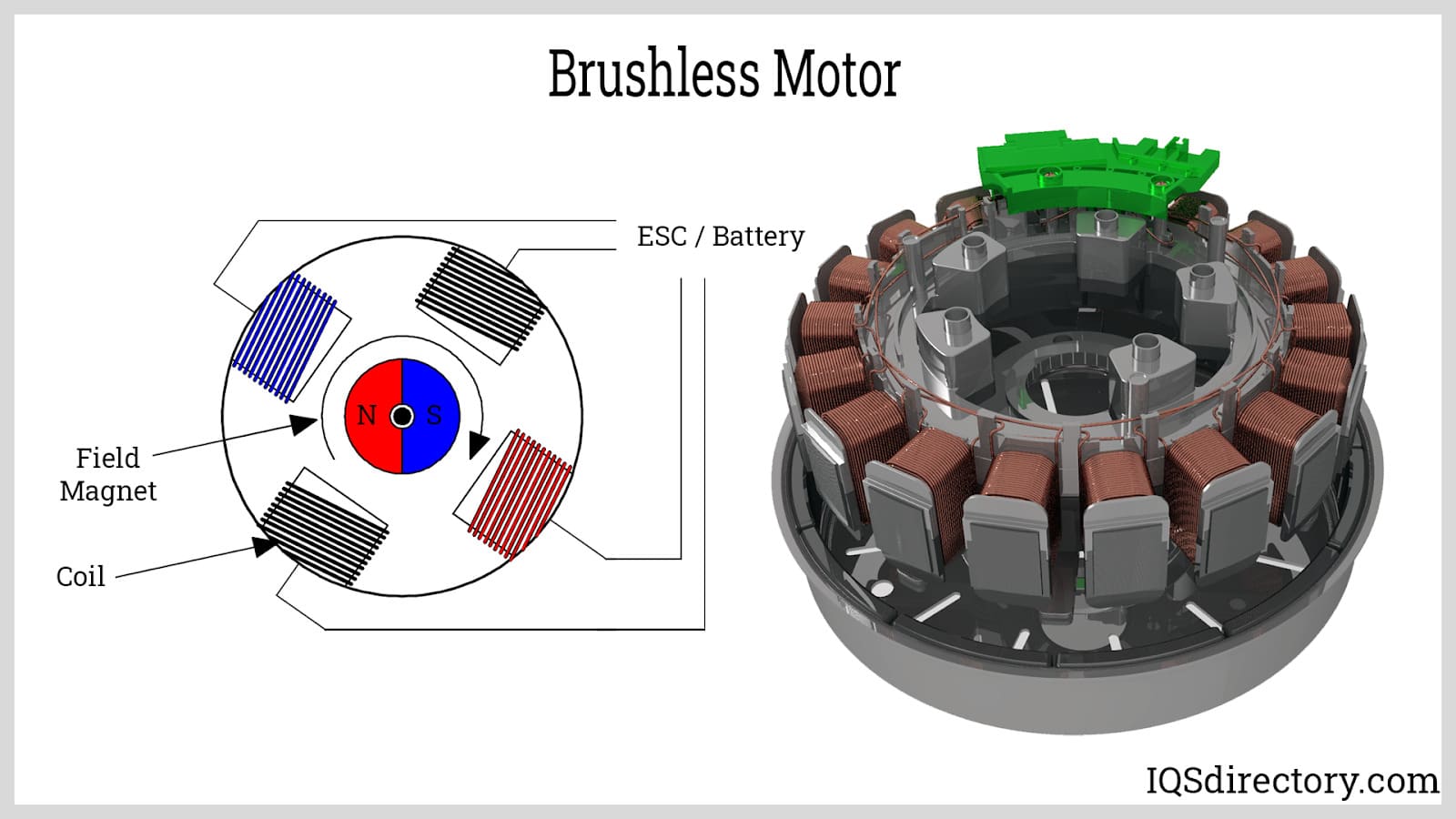

A brushless motor is a synchronous motor with no brushes that uses a direct current (DC) electric power supply.

What Is a Brushless Motor?

The brushless motor uses an electronic controller for switching DC currents to the motor’s windings, thus producing magnetic fields which effectively rotate in space and are followed by the rotor of the permanent magnet. The controller adjusts the DC pulses’ phase and amplitude to control the motor’s speed and torque. Therefore, this control system is an alternative to the mechanical commutator (brushes) used in most electric motors.

How a Brushless Motor Functions

The working principle for the brushed DC motor is the same as the brushless DC motor, including the internal shaft position feedback. However, the brushless DC motor contains only two basic parts: the rotor and the stator. The rotor refers to the rotating part and holds rotor magnets, whereas the stator is the stationary part and contains stator windings. In a brushless motor, permanent magnets are attached to the rotor and specialize in moving the electromagnets to the stator.

The high-power transistors are used to activate the electromagnets for the shaft turns. The controller performs power distribution by using a circuit that is in a solid state. Because of this DC motor design, there is no need for brushes. The advantage of a brushless DC motor is removing wear and tear on the brushes since very little heat will result from the rotating magnet. The brushless DC motors are therefore more expensive because of their efficiency.

Types of a Brushless Motor

All the types of brushless motors have the same working principles, but they differ in design according to the area of use. The brushless motor is found in two types: the outer rotor motor and the inner rotor motor.

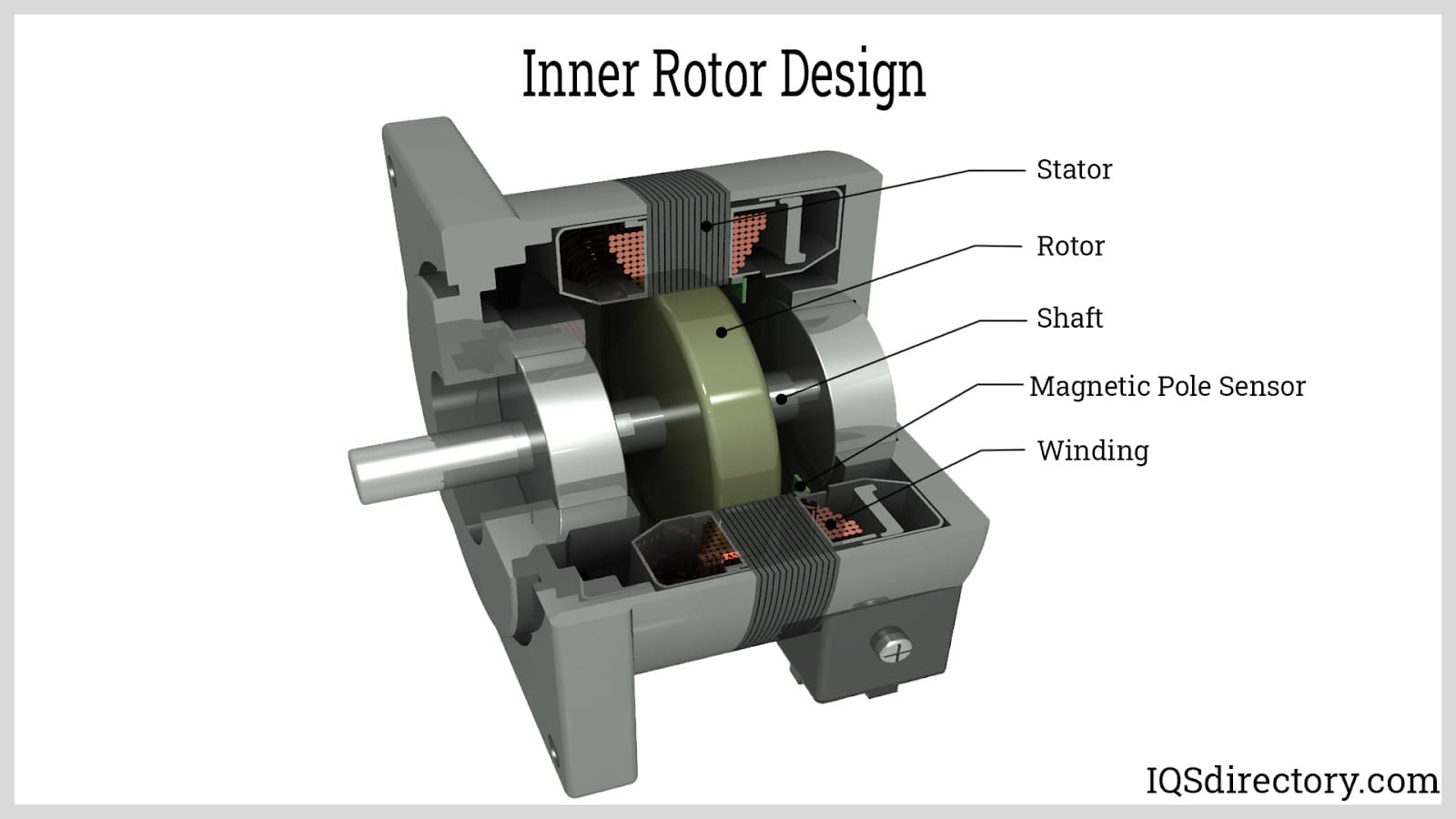

Inner Rotor Design

This type of rotor is designed in a manner whereby the rotor is located in the center of the motor, and the motor’s stator winding surrounds the rotor. The heat in the motor is dissipated easily because the rotor magnets are unable to insulate heat inside. This is because the rotor is located in the core. Inner rotor-designed motors, therefore, produce a large amount of torque and are validly used all because of this reason.

This type of rotor can produce excellent acceleration and deceleration responses due to the small rotor diameter and the low moment of inertia. Because the stator is positioned near the motor surface, there is good heat radiation, allowing for a compact motor with high output power.

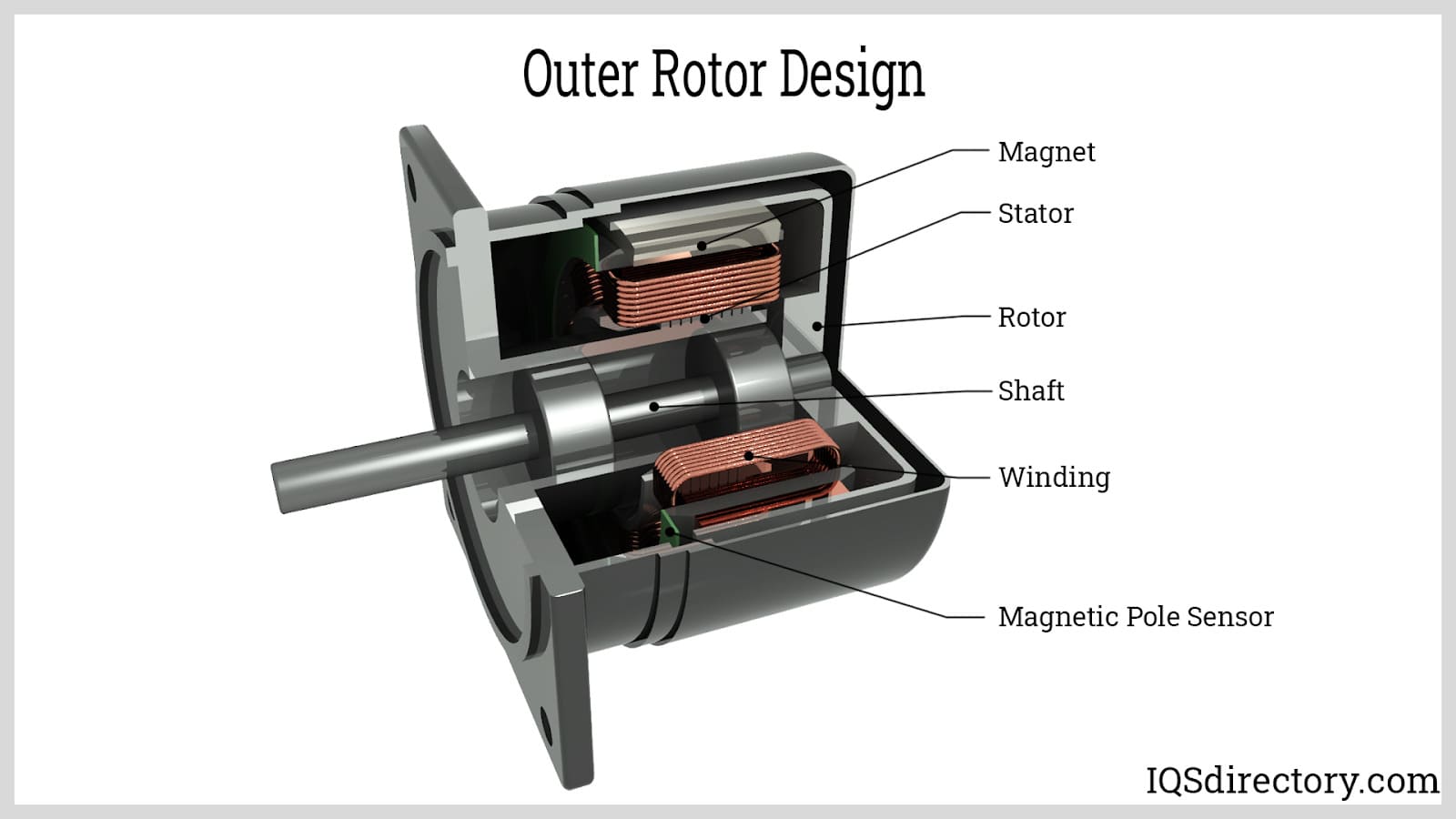

Outer Rotor Design

In this design, the rotor surrounds the winding, located in the motor’s core. The duty of the magnets in the rotor is to trap the heat of the motor inside and prevent it from dissipating. The outer rotor-designed motors operate at a lower-rated current and have low cogging torque. The contained moment of inertia is larger, and the responses in acceleration and deceleration are poor, although this type of design still provides excellent speed stability.

Because of this a cup shaped rotor is not well suited to nimble the movements. More magnets can be installed all because of the rotor’s large diameter and this results in an increased number of magnetic poles thus allowing high output power to be possible in a compact size.

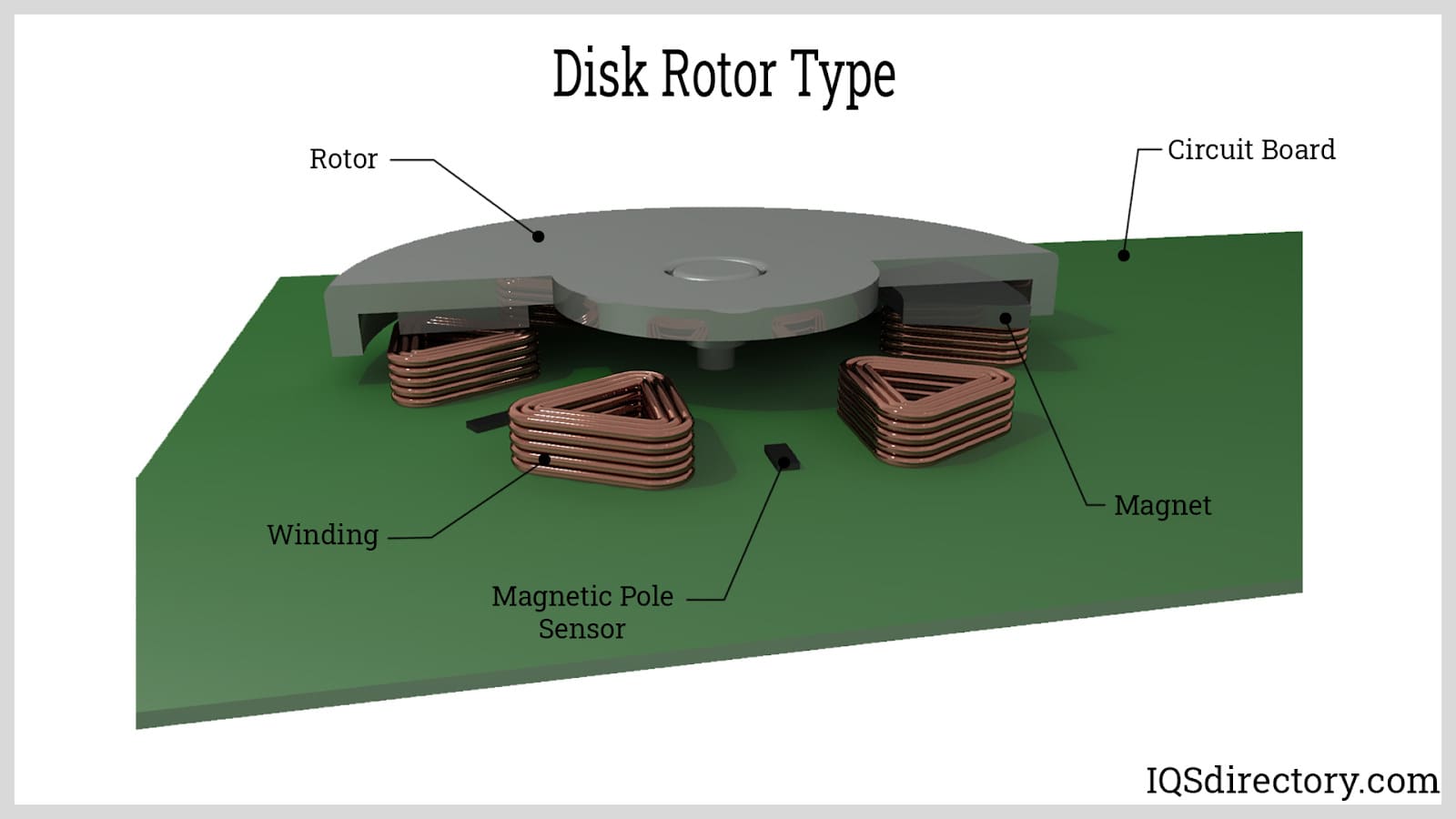

Disk Rotor Type

In this type of brushless motor, the stator is formed by mounting the windings and the magnetic pole sensors on the circuit board. The disk rotor type motor is thin because the tabular permanent magnets are placed on the rotor surface to allow them to face the stator. The load is installed on the rotor because there is no shaft. This type maintains a stable and fixed speed with a light load. This type is generally used in disk drives for DVDs.

Applications and Uses of Brushless Motors

Brushless motors are used in areas such as for devices like computer hard drives and DVD players. They can also be used to power the small cooling fans found in electronic devices. They are also used for gramophones and can be used in cordless power tools to increase efficiency.

Choosing the Right Brushless Motor Supplier

For the most positive outcome when purchasing a brushless motor from a brushless motor supplier, it is important to compare several companies using our directory of brushless motor suppliers. Each brushless motor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each brushless motor company website using our proprietary website previewer for an understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple brushless motor companies with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

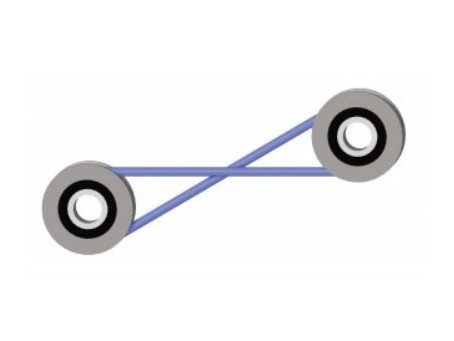

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services