AutomationDirect.com specializes in providing a wide range of electric motors to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower industries to optimize their operations...

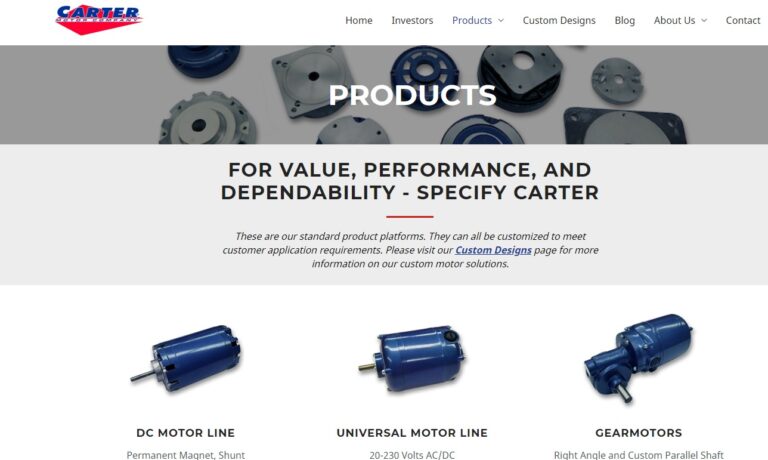

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

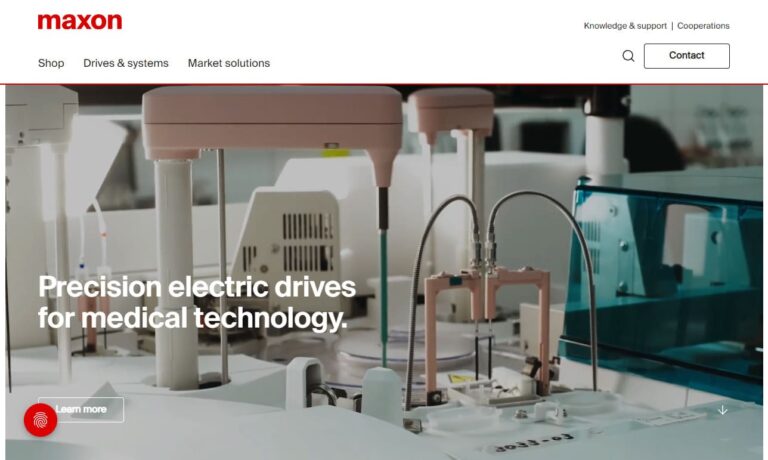

maxon manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control electronics to complement its...

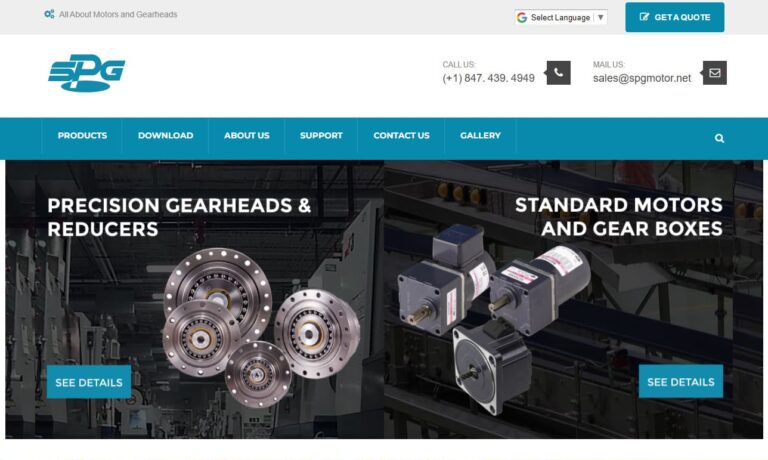

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the electric motor market in innovation & advanced quality assurance. Our AC motors, DC motors & gearheads are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE.

More Servo Motor Manufacturers

A servo motor is an electric motor that utilizes feedback to control its motion. They are widely used in various industries, including robotics, manufacturing, and aerospace. Servo motors are known for their precise control, high torque, and speed capabilities, which make them an ideal choice for applications that require accuracy and efficiency.

The history of servo motors can be traced back 1834 when the first working rotating electric motor was developed by Mortiz Herman Jacobi. Since then, servo motors have gone through various technological advancements, making them one of the most important components in advanced technologies.

Components of a Servo Motor

A servo motor consists of several components, including:

Stator and rotor: The stator is the stationary part of the motor, and the rotor is the rotating part. The stator generates a magnetic field, which interacts with the magnetic field generated by the rotor to produce motion.

Feedback device: The feedback device is used to measure the motor's position, speed, and other parameters. This information is used to adjust the motor's performance, ensuring precise control.

Control circuit:The control circuit processes the feedback information and sends signals to the motor to adjust its position, speed, and other parameters.

Power supply: The power supply provides electrical energy to the motor, enabling it to produce motion.

How Servo Motors Work

Servo motors work by utilizing feedback to control their motion. The feedback information is used to adjust the motor's performance, ensuring precise control. There are two types of servo motor systems, closed-loop and open-loop.

Closed-loop systems: In a closed-loop system, the feedback information is used to adjust the motor's performance in real-time. This results in precise control and accuracy.

Open-loop systems: In an open-loop system, the motor's performance is not adjusted in real-time based on feedback information. This results in less precise control and accuracy.

The speed and torque of a servo motor are closely related. As the load on the motor increases, the speed decreases, and the torque increases. Conversely, as the load on the motor decreases, the speed increases, and the torque decreases.

Types of Servo Motors

There are various types of servo motors, including:

AC vs. DC servo motors: AC servo motors are commonly used in high-speed, high-precision applications that require accurate positioning, such as industrial robots and CNC machines. DC servo motors are ideal for applications that require high torque at low speeds, such as printing presses, conveyors, and material handling equipment.

Linear vs. rotary servo motors:v Linear servo motors are ideal for applications that require precise linear motion, such as semiconductor manufacturing equipment, pick-and-place machines, and 3D printing. Rotary servo motors are used in applications that require rotational motion, such as CNC machines, packaging equipment, and robotics.

Brushed vs. brushless servo motors: Brushed servo motors are commonly used in low-cost applications that require moderate performance, such as hobbyist robotics and consumer electronics. Brushless servo motors are used in high-performance applications that require high torque, speed, and accuracy, such as aerospace and defense, medical equipment, and industrial automation.

Overall, the application of servo motors is highly dependent on the specific requirements of the application. Factors such as speed, torque, accuracy, and cost all play a role in determining the most suitable type of servo motor for a particular application.

Factors to Consider with Servo Motors

Servo motors have some limitations, including:

Cost: Servo motors are typically more expensive than other types of motors, making them less suitable for low-cost applications.

Complex control systems: Servo motors require complex control systems to operate effectively, which can increase design and maintenance costs.

Maintenance requirements: Servo motors require regular maintenance to ensure they continue to operate effectively and efficiently.

Benefits of Servo Motors

Despite these limitations, servo motors offer several benefits, including:

Precise control and accuracy: Servo motors are known for their precise control and accuracy, making them an ideal choice for applications that require high levels of precision.

High torque and speed capabilities: Servo motors are capable of producing high torque and speed, making them suitable for applications that require high levels of power.

Energy efficiency: Servo motors are energy-efficient, which helps to reduce operating costs and minimize environmental impact.

Versatility in applications: Servo motors can be used in a wide range of applications, making them a versatile solution for various industries.

Applications of Servo Motors

As just mentioned, servo motors are used in various industries and applications. We examine some of these applications for various industries below.

Robotics and automation: Servo motors are used extensively in robotics and automation to provide precise control and motion.

Manufacturing and assembly: Servo motors are used in manufacturing and assembly applications to control various processes, such as positioning, cutting, and welding.

Aerospace and defense: Servo motors are used in aerospace and defense applications, such as controlling the movement of aircraft wings and missiles.

Medical equipment: Servo motors are used in medical equipment, such as MRI machines and surgical robots, to provide precise control and motion.

Entertainment and gaming: Servo motors are used in entertainment and gaming applications to create realistic motion and force feedback.

Choosing the Correct Servo Motor Supplier

To ensure you have the most beneficial outcome when purchasing servo motors from a servo motor supplier, it is important to compare several companies using our directory of servo motor suppliers. Each servo motor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each servo motor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple servo motor companies with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

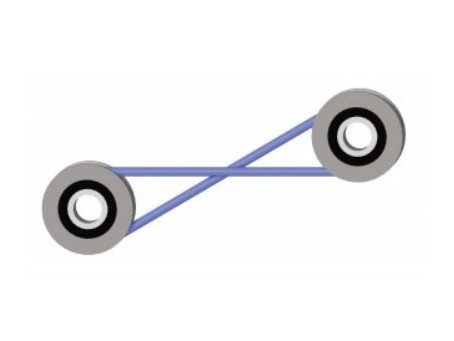

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services