We manufacture motors, motion control and rotating products for OEMs. The electric motors obtainable through us include AC motors, AC/DC motors, brushless DC motors, stepper motors.

Since our inception in 1932, Carter Motor manufactures AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, and many others. All of our products are designed and assembled here in the USA. Our team is here to help you determine the best motor to fit your application and to ensure the process is efficient and stress-free. We are...

The products of Composite Motors, Inc. all undergo the same AS9100 certified design, manufacture and testing protocol. These products include Brushless DC motors, motor drivers, Lithium Ion batteries and Battery Management Systems, gear motors and linear actuators. All products are made in the USA from raw materials. Visit our website to learn more and to view our newest products.

For custom-designed and -manufactured gear motors, contact us. We’ve been doing this business since 1958. So, for either permanent magnet AC motors or shaded pole induction DC motors, we’re the ones to get in touch with. Our website contains a downloadable motor design sheet—we welcome you to use it.

At Electric Motor solutions, our goal is to provide the best motors and equipment to meet the needs of your application. Products include linear actuators, electric motors, speed reducers, custom motors, vacuum cleaner motors, AC motors, and more.

American Electric Motors is a full service shop offering total sales & repair service, from A.C. motors, pump motors & servo motors to 5,000 H.P. D.C. motors. We stock & sell all types of new motors, pumps & brakes, plus our large inventory of used & remanufactured electric motors can save you thousands.

Connect With Recommended Electric Motor Suppliers

Provide us with your project specifications, and we’ll connect you with our network of qualified plating & coating suppliers who can give you a free proposal. Our team has been manually sourcing and curating the best U.S. manufacturers for over 20 years.

Request for QuoteWe're the #1 destination for finding U.S. Manufacturers

More Electric Motor Manufacturers

Electric motors are devices that turn electrical energy into usable mechanical energy. They achieve this by harnessing the mechanical force, or energy, produced during the interaction of an electrical current and a magnetic field. This electrical energy comes from alternating current (AC) or direct current (AC) charges from a power grid or battery.

Electric Motor Applications

Both AC and DC electric motors have one general application–powering machinery. In this context, machinery can be anything from a semi-truck to an electric toothbrush.

Electric motors power products in countless industries, including electronics, construction, home and office supplies, appliances (mixer motors, refrigerator motors, etc.), automotive manufacturing, transportation, and industrial manufacturing. The largest electric motors are used for applications like pipeline compression, ship propulsion, and pumped-storage, while the smallest electric motors can fit inside electric watches.

Electric motors have several applications, such as electric vehicles, appliances, power tools, fans, and hybrid cars. The interaction of magnetic and electric fields is crucial to the operation of an electric motor. Electric motors are divided into two categories; AC motors and DC motors. The AC motor is powered by alternating current, whereas the DC motor is powered by direct current.

History of Electric Motors

Electric motors got their start in the 1740s, when a Scottish monk named Andrew Gordon created the first electrostatic device. Around 60 years later, in 1820, French physicist André-Marie Ampère discovered how one can produce a mechanical force by facilitating interactions between two current-carrying wires. He wrote down this principle, and it later became known as Ampère’s Force Law. From his name we also gained the SI base unit of electric current measurement, the ampere or amp.

The year after Ampère discovered Ampère’s Force Law, British scientist Michael Faraday successfully conducted experiments demonstrating this principle. First, he dipped a wire in mercury and attached a permanent magnet to it. Then, he passed a current through the wire. When the current moved through the wire, the wire rotated around the magnet. What this proved was that the current created a circular magnetic field around the wire. In 1822, a man named Peter Barlow conducted a similar, but updated, experiment. During his experiment, he dipped the tips of a star shaped wheel (the Barlow wheel) in mercury as it rotated. His results of his experiment echoed Faraday’s.

Experiments like these established certain principles, like electromagnetic induction, that later scientists and engineers could use as a jumping off point. For example, in 1827, Hungarian priest and scientist Ányos Jedlik built the first recognizable electric motor–it contained a rotor, stator, and commutator. Several years later, he built a model vehicle that ran using an electric motor. In 1832, British scientist William Sturgeon built the first DC electric motor. In 1834, American blacksmith Thomas Davenport invented a battery-powered electric motor with which he powered small model cars on tracks. Three years after that, Davenport and his wife Emily patented the design for the first electric motor that could be used commercially. In 1840, he used his electric motor to power machine tools and a printing press in order to print his own newspaper on mechanics. This was the first ever newspaper to be printed using electric power. Davenport’s inventions were ingenious, but because batteries were not yet economically viable, he ended up going bankrupt.

Around this same time, German physicist and engineer Moritz von Jacobi created a rotating electric motor with which he could power a small electric boat across a river. In 1871, a Belgian electrical engineer named Zénobe Gramme built the first DC motor that made any money. In 1887, Nikola Tesla invented the AC motor, a product that uses alternating current and does not require a commutator. Around this same time, in 1886, American Frank J. Sprague invented the first non-sparking DC-motor that could keep moving at the same speed, regardless of load. Between 1887 and 1888, Sprague invented electric trolleys, which engineers put into use first in Richmond, Virginia. In 1892, he invented both the electric elevator and designed Chicago’s L system, known more formally as the South Side Elevated Railroad.

During the 20th century, electric motors changed the world. They reduced labor everywhere, from the factory floor to the home, they made machines more efficient, they increased standards of living, they allowed for the production of better products, and they expanded the possibilities of travel. Today, electric motors are an integral part of our lives.

Electric Motor Design

When selecting or designing custom motor products for you, electric motor manufacturers will consider different aspects of your application, including how fast you want your engine to go, how often you will use it, the environment in which you will use it, and load details (weight, location, etc.). Based on those factors, they will decide on AC power vs. DC power, horsepower/watts (power output), RPM (rotations per minute), speed variability vs. fixed rotation speed, and current ratings. Manufacturers can also vary your electric motor products by the number of rotors and stator magnetic poles and sizes. Find out more by going over your application with potential suppliers.

Electric Motor Features

Components

Generally speaking, electric motors consist of a rotor, a stator, windings, an air gap, and a commutator.

Rotor

In this context, the rotor is a moving part that delivers mechanical power when it moves the shaft. To achieve this turning motion, the rotor is usually designed with built-in current-carrying conductors that interact with the magnetic field generated by the stator. However, in some cases, the rotor carries the magnets while the stator holds the conductors.

Stator

Unlike the rotor, the stator does not move. Rather, it is the fixed component of the motor’s electromagnetic circuit. Generally, it consists of a core and either permanent magnets or windings. This core is made up of several thin metal sheets, called laminations, which are used to reduce energy losses.

Windings

Windings are coiled wires. When they are wrapped around the core, and after they are energized with current, the purpose of these coils is to form magnetic poles.

Air Gap

Next, the air gap is the distance between the rotor and the stator. The air gap provides most of the low power factor at which motors operate, by increasing and decreasing the magnetizing current as needed. So, because a large air gap has a strong negative effect on a motor’s performance and may present mechanical problems, losses, and noise, the air gap should be as small as possible.

Commutator

Finally, the commutator is a part used to periodically switch current direction between the external circuit and the rotor. It is used with most DC motors and with universal motors. The commutator is composed of a cylinder made up of several metal contacts, or slip rings, segments, and an armature upon which the segments rotate. Two or more electrical contacts, called brushes, make sliding contact with the segments by pressing up against them as they turn, allowing the current to flow through them and reach the rotor.

Configurations

Various electric motor configurations include salient pole, non-salient pole, and shaded pole configurations, each designed with distinct characteristics and applications

Salient Pole

The salient pole configuration features protruding poles on the rotor, resulting in a larger air gap between the rotor and the stator. This design is commonly used in synchronous motors, where direct current is passed through the rotor winding, creating a magnetic field that aligns with the stator’s rotating magnetic field. Salient pole motors offer high torque and are suitable for applications requiring variable speed and precise control, such as industrial drives and generators. However, they can be more challenging to manufacture and may have lower efficiency due to increased losses in the larger air gap.

Non-Salient Pole

In contrast, the non-salient pole configuration has a smoother rotor surface with poles distributed evenly around the circumference. This design is commonly found in induction motors, where alternating current in the stator induces a current in the rotor, creating a magnetic field that follows the stator’s rotating field. Non-salient pole motors are simpler to manufacture and maintain, making them more cost-effective and reliable. They are widely used in various industrial and commercial applications, such as pumps, fans, and compressors. While they offer good efficiency and robustness, they may not provide the same level of control as salient pole motors, limiting their application in precise speed control systems.

Shaded Pole

A third pole configuration, Shaded pole motors are a type of single-phase induction motor with additional copper or aluminum shading coils placed on one side of the pole. When power is applied, these coils create a time-delayed magnetic field, resulting in an uneven distribution of magnetic flux. This asymmetry produces a rotating magnetic field that drives the rotor to start spinning. Shaded pole motors are commonly used in small appliances like fans, blowers, and refrigerators due to their simple design, low cost, and reliable performance. However, they have relatively low efficiency and low starting torque, making them unsuitable for heavy-duty applications.

In summary, each electric motor configuration has its unique advantages and drawbacks. Salient pole motors offer high torque and precise control but can be less efficient. Non-salient pole motors are cost-effective, reliable, and widely used, though they may lack advanced control capabilities. Shaded pole motors are simple and economical, but they have lower efficiency and limited starting torque. Selecting the appropriate motor configuration depends on the specific application’s requirements, balancing factors such as performance, efficiency, and cost.

Electric Motor Types

Types by Current Source

AC motors are powered by applied alternating currents. The alternating currents, which move through coils, creates a rotating magnetic field, which in turn provides torque to an output shaft. They do not require a commutator. Common AC power sources include inverters, generators, and power grids.

DC motors get their power from direct currents. The voltage generated by the currents causes an armature winding to rotate, while a non-rotating armature field frame winding acts as a permanent magnet. Users of DC motors can manipulate their speed by adjusting the field frame current or changing the applied voltage. DC currents are often provided by rectifiers, electric motor vehicles, and batteries.

Universal motors can operate using both alternating and direct currents.

Types by Internal Construction

Brushed motors, sometimes called commutated electric motors, are one of two major types of electric motors, as categorized by internal construction. Brushed motors, which almost always use a direct current, get their name from the commutator, which comes with several brushes. These brushes are always made of a soft conductive material; almost exclusively, manufacturers use carbon, sometimes with copper powder mixed in for improved conductivity. The five main styles of brushed motors are separately-excited motors, DC series wound motors, permanent magnet DC motors, DC compound motors, and DC shunt wound motors.

Brushless motors are much more efficient than brushed motors, and they are rapidly replacing them. These motors, instead of using brushes, use sensors known as Hall effect sensors, to transfer current. They are made up of a 3-phase coil, a permanent magnet external rotor, drive electronics, and the sensor. A 3-phase coil is a motor element that references another type of motor classification, based on the motor’s means of motion.

Gear motors use gear heads to vary speed.

Electric hub motors are motors built into the hub of a wheel. They directly drive the wheel.

Types by Means of Motion

The most common motor motion classifications include 3-phase motors, single phase motors, linear motors, stepper motors, and 12V motors.

Three-phase electric motors boast both a fairly simple design and high efficiency. Usually a type of induction motor, 3 phase motors function using three alternating currents, which distribute converted mechanical energy.

Single phase motors are another example of an induction motor. This time, they use a single, or single phase, motor power source, which is generally an alternating current.

Linear motors provide mechanical energy in a straight, or linear, line. In other words, linear motors provide motion over a single plane.

Stepper motors are a lot like 3-phase synchronous motors. The main distinction between the two is simply that, while 3-phase synchronous motors rotate continuously, stepper motors must continuously start and stop. Stepper motors are common in 3D printers and robots.

12V motors generate motion using twelve volts of electric power, which is standard.

Types by Energy Conversion Method

Lastly, electric motors convert energy differently. Motors are divided thus into synchronous motors, induction motors, electrostatic motors, and servo motors.

Synchronous motors are a type of AC motor. They convert voltage into energy using a passing current and a rotor that moves at the same rate. Together, these elements create a rotating magnetic field. Synchronous motors offer their ability to maintain constant speeds while changing torque.

Induction motors, sometimes called asynchronous motors, function using the principle of electromagnetic induction. Basically, they work when an electrical conductor moves through a magnetic field and subsequently produces voltage. Induction motors are less expensive than synchronous motors.

Electrostatic motors work by harnessing the attraction and repulsion of an electric charge. They usually use a lot of power, but they are available as smaller models that use lower voltages. For example, small electrostatic motors are common components of micro-mechanical systems (MEMS).

Servo motors work using servomechanisms (servos) that sense errors and correct them automatically. They also have built-in microcontrollers that allow users to prompt them to move exact numbers of degrees whenever they want. Servo motors are exceptionally small. They are common in robotic actuators, remote-control cars, and hobby aircrafts.

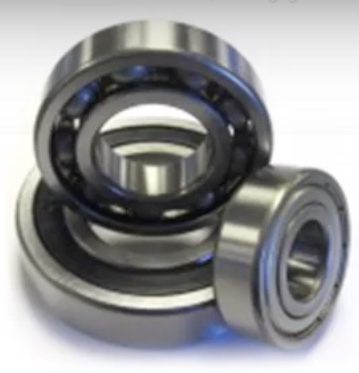

Accessories

Accessories for electric motors play essential roles in enhancing motor performance, safety, and functionality. Phase converters are used to convert power between single-phase and three-phase systems, enabling the operation of three-phase motors where only single-phase power is available, and vice versa. Bearings are crucial components that support the motor’s shaft, reducing friction and allowing smooth rotation. Fan covers protect the motor’s cooling fan, preventing debris and foreign objects from entering the motor and potentially causing damage. Motor kits and mounting kits provide necessary components and hardware for installation and assembly, ensuring a secure and proper fit.

Rain shields shield the motor from water and environmental elements, safeguarding it against moisture and corrosion, particularly in outdoor applications. Brake kits are used to add braking capabilities to motors, enabling quick stopping or holding the motor in place when powered off. Remote controls offer convenient operation and control from a distance, suitable for scenarios where manual access to the motor may be challenging. Speed/voltage controllers regulate the motor’s speed or voltage, allowing precise control over the motor’s performance, speed, and torque.

Conduit boxes are used to house electrical connections and protect them from environmental factors, ensuring a safe and organized wiring setup. Determining the need for these accessories generally depends on the specific application requirements and environmental conditions. For instance, if an electric motor operates in a wet or dusty environment, a rain shield would be essential to protect it from water and debris. Motor kits and mounting kits are necessary during installation to ensure a proper and secure setup. Brake kits may be required in applications where precise motor control and stopping are crucial, such as in heavy machinery. Remote controls and speed/voltage controllers are useful when operators need to adjust motor parameters from a distance or require variable speed control. In summary, selecting the appropriate accessories for electric motors involves considering the application’s needs, environmental conditions, and the desired level of control and safety.

Electric Motor Standards

In the United States, standards for electric motors are established and maintained by various organizations, with the National Electrical Manufacturers Association (NEMA) being one of the primary bodies responsible for setting standards related to electric motors. These standards are designed to ensure safety, performance, and efficiency in electric motor manufacturing and usage. They specify requirements for motor design, materials, testing procedures, energy efficiency levels, and more.

The general purpose of these standards is to promote uniformity, reliability, and interoperability in the electric motor industry. By adhering to these standards, manufacturers can produce motors that meet consistent quality levels, and consumers can expect reliable and safe products. Specific standards may address different aspects, such as NEMA MG 1, which covers general motor specifications, NEMA MG 10, focusing on energy efficiency of motors, and NEMA MG 11, related to motor application, installation, and maintenance guidelines.

The benefits of these standards are multifold. First and foremost, they ensure the safety of electrical systems and protect users from potential hazards associated with substandard or faulty motor designs. Standardized testing procedures also allow for accurate performance comparisons between different motor models, aiding consumers in making informed decisions. Additionally, standards help drive energy efficiency improvements, leading to reduced energy consumption and lower operating costs for end-users. Moreover, conformity to standards facilitates international trade, as compliance with recognized standards is often a prerequisite for market access in many countries.

If these standards are not complied with, the consequences can be severe. Non-compliant electric motors may pose safety risks, leading to electrical fires, malfunction, or even injury to users. Inefficient motors may result in higher energy consumption and increased utility bills for consumers. Moreover, non-compliance with industry standards can damage a manufacturer’s reputation and credibility, leading to potential legal consequences and the loss of market trust. Therefore, adherence to established standards is critical for manufacturers, consumers, and the industry as a whole, promoting a safer, more efficient, and reliable electric motor market.

Common Causes of Electric Motor Failure & How to Protect Against it

Causes

Electrical Overload

An excessive current flow within the engine windings causes electrical overload. This can be caused by a low power supply, leading to a higher torque drawing of the motor. It can also be caused by short circuits or an excessive supply of voltage.

Overheating

Overheating is caused by low power quality or high temperature operating conditions. Approximately 55% of motor insulation failures occur because of overheating.

Low Resistance

Low resistance is the most frequent type of engine failure and perhaps the hardest to overcome. The breakdown of the insulation of the windings is caused by corrosion, overheating, or physical damage.

Operational Overload

Operational overload accounts for up to one-third of all engine failures and occurs when the engine is overloaded. This results in insufficient torque, electrical overloads, or possible overheating that can wear components like rollers and engine winding.

Electric Motor Protection

Motors are protected by a variety of motor protection systems. Depending on the motor’s activity, motor protection is classified into several types. The various motor protection categories are detailed below:

Overload Protection

Overload protection is a kind of safety feature that protects against mechanical overload. Overload problems can cause the motor to overheat, which can cause damage to the motor.

Low Voltage Protection

The safety unit or device is used to disconnect the engine from the voltage source or power source if the voltage drops below the electric motor rated value. When the voltage balances to a normal value, the engine starts running again.

Overcurrent Protection

The motor protection unit trips whenever excess current passes through the motor. Therefore, circuit breakers and fuses should be used for the Protection of the various engines.

Phase Failure Protection

The Protection against phase failures is used to protect the motor when the motor is being used during any phase failure. It is usually used in three-phased engines, and the motor disconnects from the power source during failure at any stage.

Things to Consider About Electric Motors

If you’re looking for an electric motor, the first thing you need to do is make sure you know your specifications. We recommend, before calling any manufacturers, that you list everything you’re looking for (or not looking for), including your application details, your budget, your delivery deadline, your post-delivery service preferences (installation assistance, tech support, etc.), and your standard requirements. Discussing these points at length with an electric motor company will help you know if you are the right fit for one another.

To find said “right fit,” check out the high-quality manufacturers we have listed on this page. Look over their profiles and webpages to see if they might work for you. Pick out three or four top contenders, then give them each a call to talk about your application. Once you’ve spoken with each of them, compare and contrast your conversations, and pick the one you believe will offer you the best service within your budget and timeframe. Good luck!

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services